Are you looking for a way to stand out among the competition for a factory manager position? A good resume is the most important part of your search. By crafting an effective resume and providing the appropriate details, you will be able to demonstrate your qualifications and experience to potential employers. This guide will provide you with a comprehensive overview of how to create a compelling factory manager resume, along with some resume examples to help you get started.

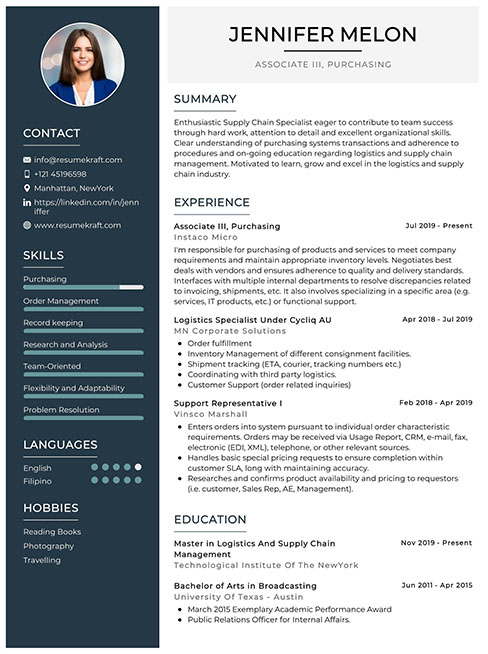

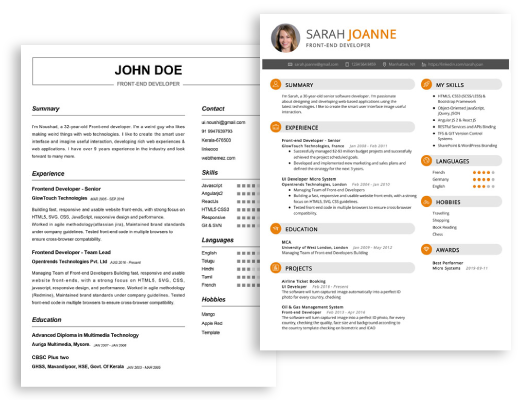

Factory Manager Resume Sample

If you didn’t find what you were looking for, be sure to check out our complete library of resume examples.

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

Factory Manager Resume Examples

John Doe

Factory Manager

123 Main Street | Anytown, USA 99999 | Phone: (123) 456-7890 | Email: john.doe@email.com

Highly organized, results- driven professional with 8+ years of experience as a Factory Manager. Skilled in creating efficient factory processes as well as managing personnel and equipment. Possesses a comprehensive understanding of quality assurance and health and safety regulations. Proven ability to manage large teams and create efficient workflows, while ensuring the highest quality of work.

Core Skills:

- Manufacturing Process Optimization

- Personnel Management

- Quality Assurance

- Health & Safety Protocols

- Inventory & Supply Chain Management

- Performance & Budget Management

- Strong Leadership Skills

- Problem Solving & Decision Making

- Communication & Interpersonal Skills

Professional Experience:

Factory Manager, ABC Industries, 2016 – Present

- Manage day- to- day operations of a 35,000 sq. ft. manufacturing facility with a staff of 60

- Create efficient working processes and ensure adherence to company policies & procedures

- Ensure compliance with all health & safety regulations and implement safety training for employees

- Develop and implement a production plan to ensure timely completion of projects

- Monitor the flow of work and provide guidance to employees

- Oversee the inventory & supply chain and manage the purchasing & distribution of materials

- Manage personnel & personnel issues, including hiring, scheduling, training & performance reviews

- Direct the maintenance of equipment and ensure optimal performance

Education:

Bachelor of Science in Manufacturing Engineering, University of Chicago, 2012

Factory Manager Resume with No Experience

- Experienced facilities manager with a well- rounded background in the construction, operations and maintenance of factory plants and buildings

- Demonstrated ability to effectively lead, manage and motivate personnel with a focus on safety and efficiency

- Strong problem- solving and organizational skills and an eye for detail

- Exceptional communication and interpersonal abilities

Skills

- Excellent knowledge of factory operations and processes

- Ability to read blueprints and schematics

- Strong understanding of safety regulations

- Proficient in MS Office applications

- Ability to work in a fast- paced environment

Responsibilities

- Create and implement procedures and protocols to ensure the safe and efficient operation of the facility

- Perform daily inspections of the facility and identify areas that need improvement

- Coordinate with outside vendors and contractors to ensure timely completion of projects

- Ensure the facility is in compliance with all local, state and federal regulations

- Develop and implement preventative maintenance plans to reduce downtime and increase efficiency

- Maintain records of all equipment and inventory within the facility

- Train and supervise staff on safety protocols and machinery operations

Experience

0 Years

Level

Junior

Education

Bachelor’s

Factory Manager Resume with 2 Years of Experience

Highly experienced Factory Manager with over two years managing the production of factories and manufacturing companies. Adept at project planning and production scheduling to meet customer demand. Experienced in training and motivating teams, optimizing production processes and cost efficiency. Skilled in identifying and addressing issues related to production operations and customer service.

Core Skills

- Project Planning

- Production Scheduling

- Staff Training & Motivation

- Production Process Optimization

- Cost Efficiency

- Customer Service

- Problem Solving

- Quality Control

Responsibilities

- Developed and implemented production plans to meet customer demand.

- Managed and trained teams of production workers.

- Monitored production processes and identified areas for improvement.

- Reduced costs by implementing efficient production methods and processes.

- Developed and maintained quality control systems to ensure product meets customer standards.

- Resolved customer service issues and complaints in a timely manner.

- Ensured compliance with safety regulations and standards.

- Coordinated with vendors to ensure timely delivery of materials and supplies.

Experience

2+ Years

Level

Junior

Education

Bachelor’s

Factory Manager Resume with 5 Years of Experience

A highly motivated and dedicated professional Factory Manager with 5 years of experience in managing industrial operations and production. Adept in overseeing production lines, maintaining quality assurance, meeting production goals and cost management. Highly skilled in troubleshooting and problem- solving. Possesses the capability to introduce and implement process improvements in line with the company’s objectives.

Core Skills:

- Quality Assurance

- Cost Management

- Production Management

- Industrial Operations

- Process Improvement

- Troubleshooting

- Problem- Solving

- Team Leadership

Responsibilities:

- Supervised, managed and motivated a team of production staff, whilst monitoring product quality, standards and safety

- Developed and implemented production schedules, processes and standards

- Ensured production goals were met and exceeded, within budgets and timelines

- Monitored the performance and efficiency of the production lines

- Negotiated and sourced cost effective supplies and services to maximize profits and minimize costs

- Analyzed and identified areas for improvement in manufacturing processes

- Developed and implemented policies, procedures, methods and systems to improve production, safety and reliability

- Coordinated with other departments, to ensure production requirements were met

- Ensured that health and safety standards were met and maintained in line with legal and corporate requirements

Experience

5+ Years

Level

Senior

Education

Bachelor’s

Factory Manager Resume with 7 Years of Experience

I am a factory manager with seven years of experience in the production and manufacturing industry. I have extensive knowledge in the areas of production planning and scheduling, cost control, and quality assurance. I am passionate about ensuring that production processes are running efficiently and delivering high quality products to customers. My core skills include strong problem- solving and organizational abilities, excellent communication and negotiation skills, and the ability to create innovative and cost- effective solutions. I am motivated to build teams and inspire them to reach their potential.

Core Skills:

- Production Planning and Scheduling

- Cost Control

- Quality Assurance

- Problem Solving

- Organizational Skills

- Communication and Negotiation

- Innovative Solutions

- Team Building

Responsibilities:

- Create and implement production plans to ensure efficient operation of the factory

- Monitor factory performance, analyze data, and identify areas of improvement

- Oversee the maintenance and repair of factory equipment

- Develop and implement best practices to reduce wastage and maintain cost efficiency

- Monitor and ensure quality control standards are met

- Lead and motivate teams to achieve production goals

- Manage and coordinate resources to ensure deadlines are met

- Work with vendors to negotiate contracts and manage inventory levels

- Ensure customer service standards are met and customer satisfaction is maintained.

Experience

7+ Years

Level

Senior

Education

Bachelor’s

Factory Manager Resume with 10 Years of Experience

With 10 years of experience in Factory Management, I am a highly experienced and organized leader who takes pride in leading a team of motivated individuals with a focus on quality assurance and production. I have a proven record of success in the areas of budget management, process improvement, and lean manufacturing. I am analytical, organized and a firm believer in the power of teamwork to achieve great results. My experience has enabled me to develop strong negotiation and problem- solving skills, which I use to exceed company objectives.

Core Skills:

- Leadership

- Budget Management

- Process Improvement

- Problem Solving

- Negotiation

- Teamwork

- Lean Manufacturing

- Quality Assurance

Responsibilities:

- Developing and overseeing operational plans and processes

- Identifying and implementing process improvement initiatives

- Managing the production team and providing strategic direction

- Monitoring and improving factory performance

- Conducting regular assessments of production and quality standards

- Creating and executing weekly and monthly schedules

- Maintaining labor cost effectiveness and efficiency

- Ensuring compliance with safety regulations and company policies

- Coordinating with other departments to meet company objectives

Experience

10+ Years

Level

Senior Manager

Education

Master’s

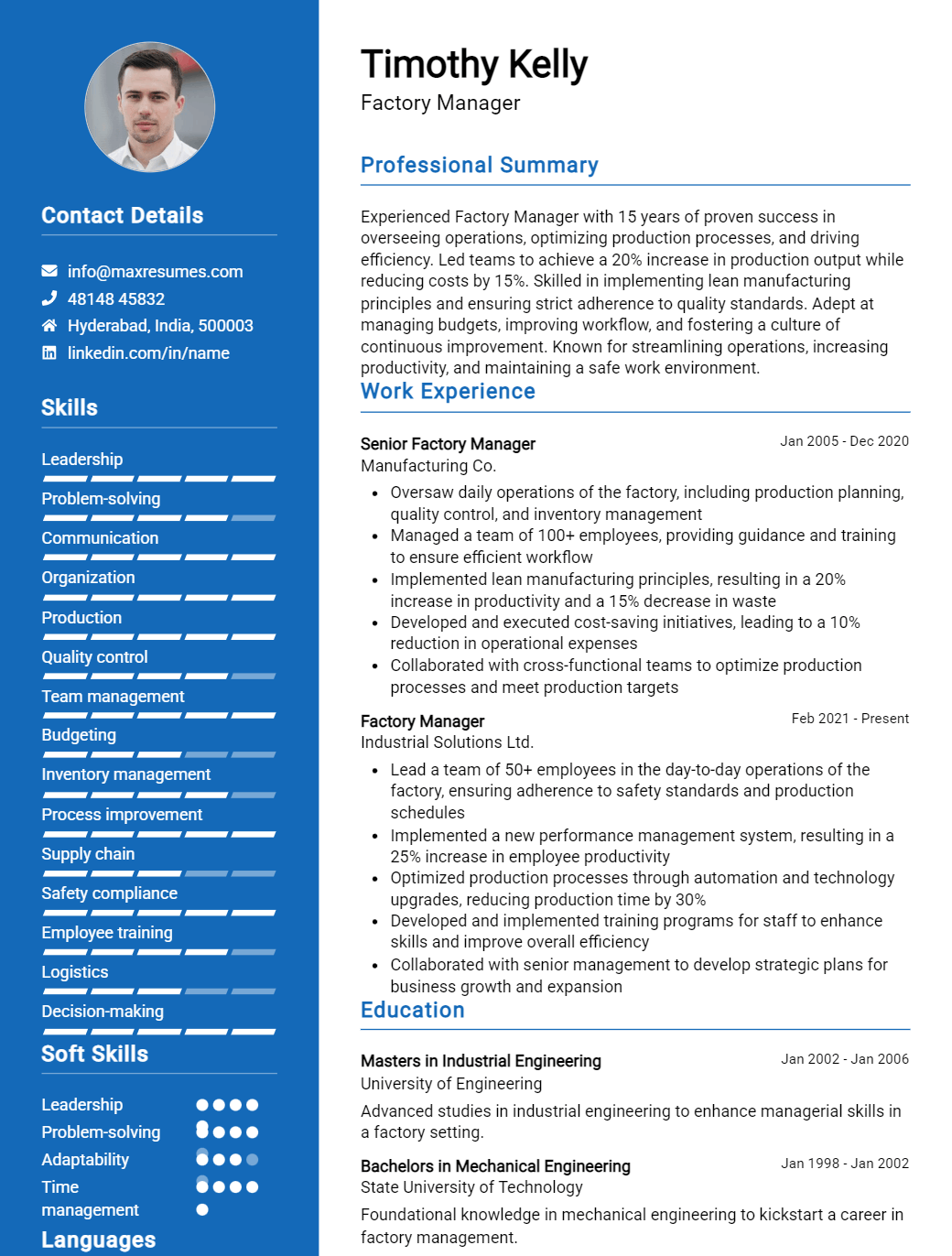

Factory Manager Resume with 15 Years of Experience

Factory Manager with 15+ years of experience leading production teams, developing quality assurance programs, and overseeing successful manufacturing operations. Experienced in hiring and coaching employees to ensure best practices, implementing safety protocols and process improvements to maximize productivity and efficiency. Proven track record of developing continuous improvement programs to reduce costs and increase throughput. Dedicated to ensuring a safe and productive work environment to maximize production goals.

Core Skills:

- Leadership & Management

- Quality Assurance

- Process Improvement

- Production Management

- Safety Protocols

- Team Development

- Budgeting & Cost Control

- Equipment Maintenance & Calibration

Responsibilities:

- Organize and oversee daily operations for a manufacturing facility with 20+ employees

- Develop, implement, and maintain production policies, safety protocols, and quality assurance procedures

- Create and manage budgets, set goals and objectives, and monitor production operations

- Recruit, hire, and train personnel while providing guidance and performance evaluations

- Maintain and repair equipment to ensure productions are running in optimal condition

- Create continuous improvement programs to reduce overhead costs, improve quality, and increase throughput

- Implement Lean Manufacturing concepts to ensure operations are running efficiently

- Develop and implement process plans to ensure customer deadlines are met

- Drive technical problem solving initiatives and provide technical guidance to production staff

- Lead monthly production meetings to analyze results and devise strategies to improve operations

- Ensure compliance with OSHA and other relevant regulations, to maintain a safe and healthy work environment

- Provide strategic direction to the team and collaborate with other departments for a more productive workflows

Experience

15+ Years

Level

Director

Education

Master’s

In addition to this, be sure to check out our resume templates, resume formats, cover letter examples, job description, and career advice pages for more helpful tips and advice.

What should be included in a Factory Manager resume?

A factory manager is responsible for overseeing the day-to-day operations of a manufacturing plant. They are in charge of ensuring production and quality goals are met, while ensuring the safety of the workers. A factory manager resume should include all of the experience, qualifications, and skills necessary to be successful in this position.

When putting together a resume for a factory manager position, here are some of the key points to include:

- Education and Licenses: Many factory manager positions require a Bachelor’s degree in a related field, such as manufacturing or industrial engineering. If you have any industry-related licenses or certifications, these should be included as well.

- Experience: Include any relevant work experience which demonstrates your expertise in factory management. This includes prior positions of increasing responsibility, as well as any successful projects or initiatives you have been involved in.

- Technical Skills: Factory management requires a strong understanding of manufacturing and production processes, as well as the associated technology. Include any particular skills and experience you have with machinery, software, or other technical aspects.

- Leadership Qualities: As a factory manager, you will be responsible for leading a team of workers. Be sure to include any applicable leadership qualities and experience, such as the ability to motivate others or provide effective direction.

- Ability to Troubleshoot: Factory managers need to be able to quickly and effectively identify and resolve issues. Include any experiences you have had with problem-solving or troubleshooting, whether in a professional or personal setting.

- Safety and Quality Standards: Maintaining safety and quality standards is a critical part of factory management. Include any experience you have with upholding such standards, whether through implementing new protocols or ensuring compliance with existing practices.

These are just some of the key points to include in your factory manager resume. By emphasizing your education and experience, as well as any relevant technical and leadership skills

What is a good summary for a Factory Manager resume?

A Factory Manager resume should be concise and to the point. It should focus on the applicant’s experience in the manufacturing industry and highlight the manager’s accomplishments and skills. It should also emphasize the areas in which the manager excels, such as problem-solving and decision-making. The resume should also include details of the applicant’s educational background, as well as any certifications or awards that the applicant may have. Finally, the resume should conclude with references and contact information for potential employers. By including these elements, a Factory Manager resume should provide an employer with an informative summary of the applicant’s background and qualifications.

What is a good objective for a Factory Manager resume?

A good objective for a Factory Manager resume should emphasize the candidate’s ability to manage the plant efficiently and effectively, as well as their technical aptitude and understanding of the plant’s production process. The following objectives can be used to demonstrate a Factory Manager’s qualifications:

- Engage in cost-effective and efficient production of quality products

- Utilize sound management and problem solving skills to maintain high standards in operations

- Implement procedures to ensure optimal safety and efficiency of the production process

- Utilize strong communication and leadership skills to train and motivate staff

- Monitor and control quality, cost, wastage, and production schedules

- Maintain records and prepare reports regarding production and other activities

- Manage budget, plan, and schedule work according to customer needs and deadlines

- Develop strategies and plans to reduce costs while maintaining high quality standards

How do you list Factory Manager skills on a resume?

When it comes to creating a resume for a factory manager position, it is important to include a section that lists out the particular skills and abilities that make you stand out from other candidates. A well-crafted list of factory manager skills will demonstrate your experience and qualifications for the position. Here are some of the key skills and abilities to include on your resume when applying for a factory manager job:

- Supply Chain Management: A successful factory manager is able to oversee the entire supply chain process, from sourcing raw materials to delivery of the finished product.

- Quality Control: Factory managers need to ensure that strict quality control measures are in place to guarantee the highest level of product quality.

- Leadership: Factory managers are expected to lead their teams and provide clear direction to ensure performance and efficiency.

- Problem-solving: As a factory manager, you need to be able to anticipate and identify potential problems before they arise and come up with solutions for them quickly.

- Operational Management: Factory managers need to be able to manage the day-to-day operations of the factory, including scheduling, budgeting, and resource allocation.

- Safety: Factory managers need to be aware of the safety regulations and procedures in place and ensure that they are followed.

- Communication: Factory managers must be able to communicate effectively with their teams, vendors, and customers.

By including a comprehensive list of factory manager skills on your resume, you can highlight your strengths and demonstrate why you are the right person for the job.

What skills should I put on my resume for Factory Manager?

A successful Factory Manager should have excellent management skills, including the ability to delegate and oversee production processes.

- Factory Managers should have a strong understanding of production processes and quality assurance.

- They should also be able to identify and resolve any problems that arise in the factory.

- Strong organizational and interpersonal skills are essential, as the Factory Manager is responsible for managing the staff, ensuring that deadlines are met, and ensuring safety standards are followed.

- Knowledge of customer service principles, computer systems, and best practices for factory operations are also important.

- Experience in the industry, as well as technical and project management skills, are also desirable.

Key takeaways for an Factory Manager resume

When it comes to creating an effective Factory Manager resume, there are some key takeaways that you should keep in mind. A good Factory Manager resume should highlight your experience in leading a team, managing production, and understanding of various aspects of the manufacturing process.

The first key takeaway is to highlight your skills and qualifications. A Factory Manager resume should include details about your production management experience, such as how many years you have been in the role, as well as any specialized certifications or training you have undergone. It is also important to include a list of your accomplishments in the role, such as any cost savings or productivity improvements you have implemented.

Another key takeaway is to emphasize your leadership skills. Factory Managers must be able to lead a team, delegate tasks, and ensure that production is being completed correctly and efficiently. It is important to highlight your ability to motivate, inspire, and manage a team, as well as any successful team building initiatives you have implemented.

Finally, it is important to include details about your understanding of the manufacturing process. This should include an understanding of safety procedures, quality control and assurance, and process improvement. You should also highlight any industry-specific certifications you have, such as a Certified Manufacturing Manager (CMM) or Certified Quality Engineer (CQE).

By keeping these key takeaways in mind, you will be able to create an effective Factory Manager resume that will help you stand out from the competition.

Let us help you build

your Resume!

Make your resume more organized and attractive with our Resume Builder