Fabrication Engineers require a specialized set of skills, knowledge and experience to create and manage the production of components and systems. With the increased demand for fabrication engineers in a variety of industries, it is important for a potential candidate to have a well-crafted resume that is able to accurately display their skills and experience. This resume writing guide will provide a number of examples and tips to help the fabrication engineer create an effective resume that helps them stand out from the competition.

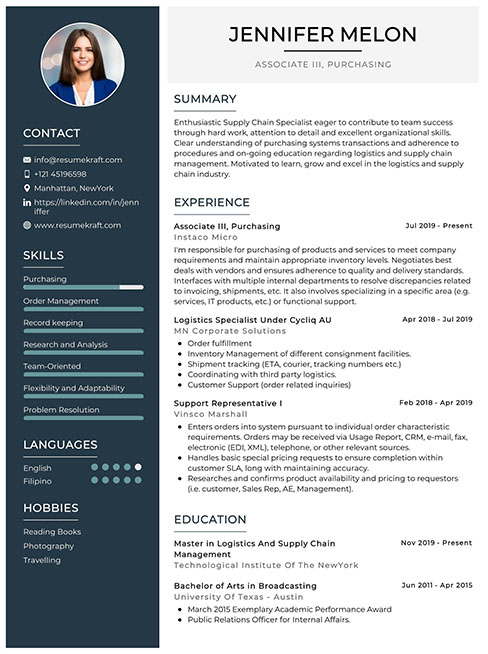

Fabrication Engineer Resume Sample

If you didn’t find what you were looking for, be sure to check out our complete library of resume examples.

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

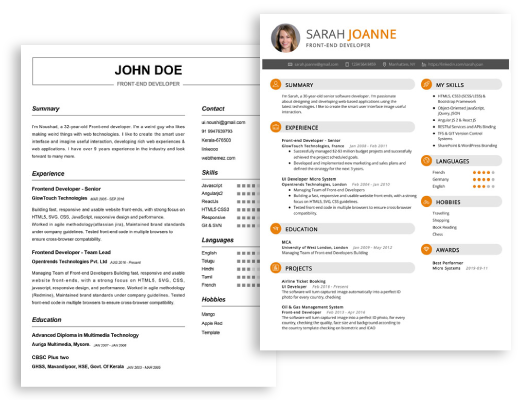

Fabrication Engineer Resume Examples

John Doe

Fabrication Engineer

123 Main Street | Anytown, USA 99999 | Phone: (123) 456-7890 | Email: john.doe@email.com

Highly motivated Fabrication Engineer with 7 years of experience in design, development and fabrication of mechanical and electromechanical products. In- depth knowledge of fabrication, welding, assembly, machining and mechanical drawings. Skilled at liaising with customers to ensure product meets specifications and meets customer requirements. Experienced in troubleshooting and resolving problems to ensure timely production of quality parts and products.

Core Skills:

- Fabrication

- Welding

- Assembly

- Machining

- Mechanical Drawings

- Problem Solving

- Product Development

- Design

- Reverse Engineering

Professional Experience:

- Design, develop, and fabricate mechanical and electromechanical products, including custom components and parts

- Develop mechanical drawings for assembly and fabrication

- Troubleshoot and resolve problems to ensure timely production of quality products

- Liaise with customers to ensure product meets specifications and meets customer requirements

- Deliver presentations to customers to explain the process and product design

- Ensure product conforms to applicable codes and regulations

- Perform reverse engineering to create product specifications

Fabrication Technician

XYZ Manufacturing Company, San Francisco, CA

2013- 2016

- Set- up and operated fabrication equipment, such as lathes, mills, presses, and hydraulic sheet metal shears

- Fabricated, welded and assembled structural steel components and other metal parts

- Followed blueprints and instructions on proper fabrication techniques

- Performed routine maintenance on fabrication equipment

Education:

Bachelor of Science in Mechanical Engineering

University of California, San Francisco

2009- 2013

Fabrication Engineer Resume with No Experience

- Recent engineering graduate passionate about applying knowledge of fabrication techniques to help design and create innovative products.

- Enthusiastic and dedicated to learning new fabrication engineering methods to stay current with industry trends.

SKILLS

- Strong knowledge of fabrication techniques and engineering principles

- Excellent written and verbal communication skills

- Insightful problem solver

- Proficient with engineering CAD design software

- Self- motivated and reliable

- Ability to effectively manage multiple tasks and remain organized

Responsibilities

- Perform detailed calculations to develop accurate fabrication plans

- Compile and analyze data to identify trends and suggest improvements to fabrication processes

- Assist in the design, development and testing of new fabrication processes

- Analyze engineering drawings to identify fabrication requirements

- Develop fabrication instructions and document results

- Collaborate with other engineers to identify and resolve fabrication flaws and develop solutions

- Ensure safety protocols are followed during the fabrication process

Experience

0 Years

Level

Junior

Education

Bachelor’s

Fabrication Engineer Resume with 2 Years of Experience

Fabrication Engineer with 2 years of experience in design, fabrication, and inspection of parts and assemblies. Skilled in the use of CAD/CAM software and proficient in reading blueprints. Experienced in overseeing the assembly process and working with different types of materials. Adept at analyzing projects, identifying issues, and developing effective solutions to complete projects on time.

Core Skills:

- CAD/CAM Software

- Blueprint Reading

- Design and Fabrication

- Assembly Process

- Procurement

- Quality Control

- IT Skills

- Troubleshooting

Responsibilities:

- Designed and built parts and assemblies for various projects.

- Developed schematics, drawings, and models using CAD/CAM software.

- Read blueprints and technical drawings to ensure accuracy of fabrication.

- Monitored assembly process and inspected finished products to ensure quality control.

- Worked with different materials including metals, aluminum, and plastics.

- Conducted research to identify new materials and techniques.

- Assisted in procurement and procurement management.

- Resolved technical issues and provided technical support.

- Maintained accurate records of all projects and updated IT systems.

Experience

2+ Years

Level

Junior

Education

Bachelor’s

Fabrication Engineer Resume with 5 Years of Experience

Fabrication Engineer with five years of experience in the design and implementation of complex systems and processes. Skilled in the use of CAD software and fabrication tools to develop and construct components, as well as the optimization of parts and assemblies. Experienced in managing multiple projects simultaneously, while meeting tight deadlines and maintaining high quality standards.

Core Skills:

- CAD design

- Fabrication tools

- Process optimization

- Project management

- Quality control

Responsibilities:

- Developed and constructed components using CAD software and fabrication tools

- Optimized parts and assemblies to reduce cost and improve efficiency

- Managed multiple projects simultaneously and met tight deadlines

- Ensured quality standards were met and maintained

- Evaluated performance and project specifications to ensure effective fabrication processes

- Assisted with the development and implementation of new fabrication processes

- Troubleshot problems with existing fabrication processes and identified solutions

- Provided technical support to fabrication teams throughout the design process

Experience

5+ Years

Level

Senior

Education

Bachelor’s

Fabrication Engineer Resume with 7 Years of Experience

Highly experienced Fabrication Engineer with 7 years of experience in the design, development and installation of various fabrication systems. Proven ability to understand customer needs and develop innovative solutions to meet them. A skilled communicator, able to work effectively in collaboration with other engineering professionals. Excellent problem- solving, critical- thinking, and organizational abilities.

Core Skills:

- Hands on experience in design, development and installation of various fabrication systems

- Strong knowledge of fabrication principles, materials, and processes

- Solid understanding of customer requirements and needs

- Ability to analyze and interpret data to make informed decisions

- Excellent problem- solving, critical- thinking and organizational skills

- Strong communication, interpersonal, and collaboration skills

Responsibilities:

- Develop and design fabrication systems to meet customer needs

- Analyze customer requirements to define fabrication processes and best practices

- Test, troubleshoot, and evaluate fabrication systems for quality assurance

- Manage and maintain fabrication and engineering records

- Ensure safe and efficient operations of fabrication systems

- Carry out fabrication process improvements and modifications

- Identify and resolve technical problems related to fabrication

- Provide technical support to other engineering teams and customers

Experience

7+ Years

Level

Senior

Education

Bachelor’s

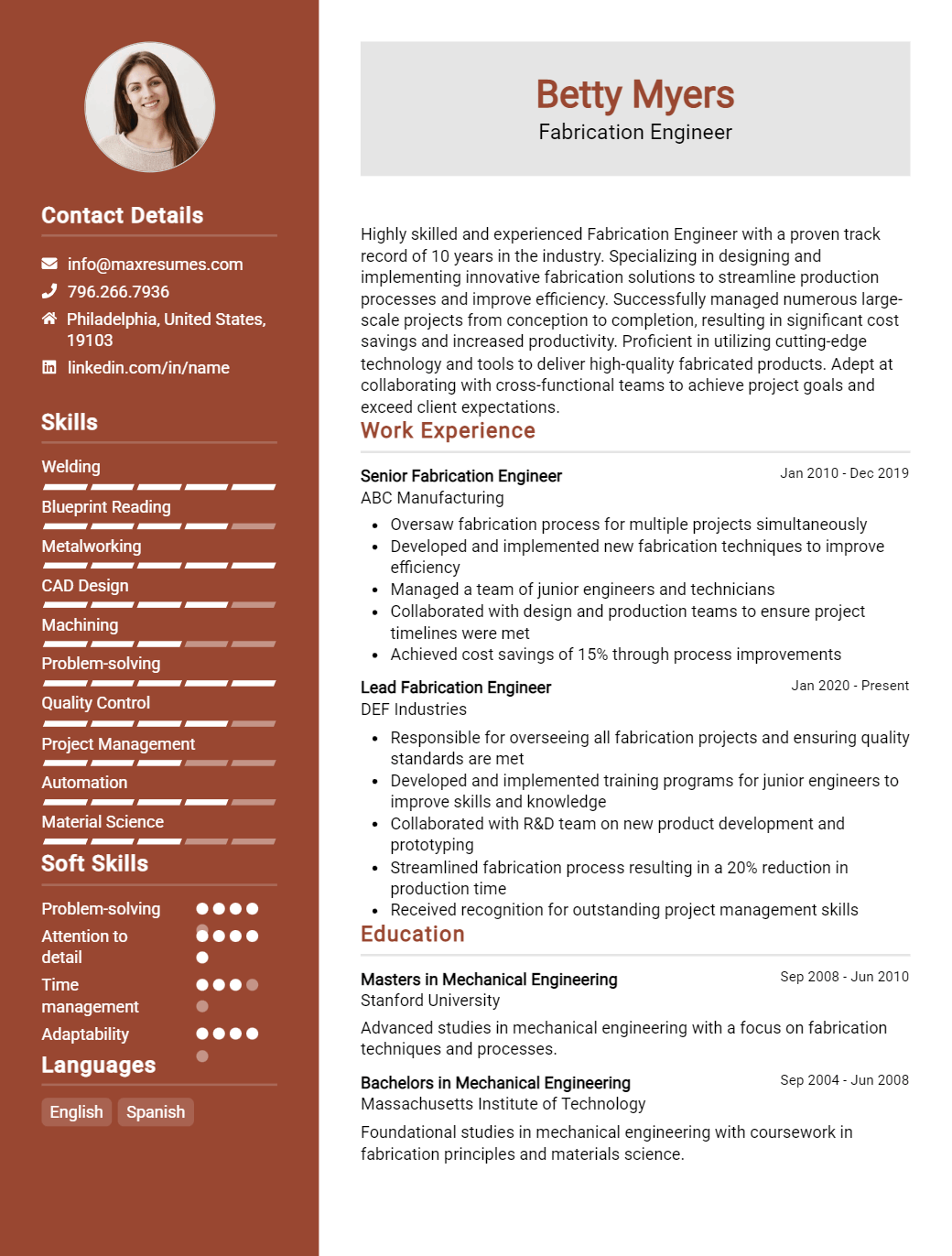

Fabrication Engineer Resume with 10 Years of Experience

Highly experienced Fabrication Engineer with a decade of professional experience in the field. Proven success in collaborating with cross- functional teams to develop and implement fabrication processes for industrial tools, machinery, and components. Adept at creating and maintaining fabrication drawings and managing the fabrication process from start to finish. Demonstrated dedication to driving cost savings through process optimization and continual improvement.

Core Skills:

- Fabrication Process Planning

- Cost Reduction Strategies

- Test & Inspection Protocols

- Quality Control

- Drawing Creation & Maintenance

- Process Automation

- Lean Manufacturing

- Root Cause Analysis

- Project Management

- Troubleshooting

Responsibilities:

- Review customer requirements and develop fabrication processes accordingly

- Develop and implement cost reduction strategies to maximize ROI

- Create and maintain drawings, documentation, and bill of materials

- Optimize fabrication processes through process automation and lean manufacturing

- Develop and implement test and inspection protocols to ensure quality control

- Manage fabrication projects from start to finish, including budget management and timeline development

- Troubleshoot issues and perform root cause analysis to develop and implement corrective action plans

- Collaborate with cross- functional teams to ensure customer satisfaction and cost savings

Experience

10+ Years

Level

Senior Manager

Education

Master’s

Fabrication Engineer Resume with 15 Years of Experience

Fabrication Engineer with 15 years of experience in the automotive manufacturing industry. Adept in developing innovative solutions for complex engineering problems. Possess a broad knowledge of fabrication and application engineering. Core skills include:

- CAD/CAM design

- Welding process design

- Fabrication process optimization

- Materials selection

- Tooling and equipment design

- CNC programming

Responsibilities:

- Developed CAD/CAM models and technical drawings for prototypes and experimental projects.

- Inspected prototypes to ensure adherence to design specification and safety protocols.

- Analyzed welding processes and optimized them to increase efficiency and reduce cost.

- Designed advanced fabrication processes and tooling combinations to meet production needs.

- Selected higher grade materials to reduce costs and improve product durability.

- Developed CNC programs for fabrication machines such as lathes, mills and presses.

- Created and updated project documentation to ensure accurate records and traceability.

- Provided technical direction to junior engineering staff and technicians.

Experience

15+ Years

Level

Director

Education

Master’s

In addition to this, be sure to check out our resume templates, resume formats, cover letter examples, job description, and career advice pages for more helpful tips and advice.

What should be included in a Fabrication Engineer resume?

Fabrication engineers use their expertise in engineering principles to design, develop, and produce fabricated components. A fabrication engineer resume should highlight an individual’s qualifications, experience, and professional achievements.

When crafting a resume for a fabrication engineer role, consider the following:

- Education: Include information about your educational background, such as your degree(s), majors, and institutions attended.

- Experience: Highlight any previous experience in engineering, fabrication, or a related field. Be sure to include details such as job title, company name, and dates of employment.

- Technical Knowledge: Demonstrate your technical knowledge through certifications, special projects, or knowledge gained through relevant courses.

- Software Skills: Mention any software skills that may be beneficial to the role, such as CAD software, AutoCAD, or other computer-aided design tools.

- Communication Skills: Showcase your ability to interact with colleagues and customers by outlining any customer service experience or collaborative projects.

- Leadership Skills: Outline any experience leading teams or taking on managerial roles, if applicable.

By including the above points in your fabrication engineer resume, you will be able to effectively convey your qualifications and make a strong impression on hiring managers.

What is a good summary for a Fabrication Engineer resume?

A fabrication engineer resume should include a concise yet detailed summary of the candidate’s professional experience and qualifications. The summary should highlight the individual’s key skills, including knowledge of welding, machining, and fabrication processes, as well as the ability to troubleshoot and solve complex engineering challenges. The summary should also demonstrate the candidate’s creative problem-solving abilities and any special certifications or awards. Finally, the summary should list any relevant experience in the engineering field, including any internships or apprenticeships, as well as any previous roles in research, development, or design. With these qualifications, the fabrication engineer resume should set the candidate apart from other applicants and demonstrate why they are an excellent fit for the job.

What is a good objective for a Fabrication Engineer resume?

A Fabrication Engineer is responsible for designing and constructing fabrications or components for industrial or manufacturing products. It’s important to have a well-crafted objective statement on your resume to show potential employers the value and expertise you can bring to the job. Here are some tips for creating an effective Fabrication Engineer resume objective:

- Explain your experience in fabrication engineering and its relevance to the job description.

- Highlight your industry knowledge and technical skills, such as metal fabrication, welding, and machining.

- Focus on your ability to work collaboratively and independently in a fast-paced environment.

- Emphasize your commitment to safety and quality control standards.

- Demonstrate your problem-solving abilities, creative thinking, and leadership potential.

With these tips in mind, your objective statement could look something like this:

A highly motivated Fabrication Engineer with 5+ years of experience in metal fabrication, welding, and machining. Dedicated to upholding strict safety and quality control standards and ensuring the successful delivery of projects. Proven ability to work autonomously and collaboratively to solve complex problems. Seeking an opportunity to utilize my knowledge and creative problem-solving skills in a challenging and rewarding Fabrication Engineering role.

How do you list Fabrication Engineer skills on a resume?

Fabrication engineers are responsible for fabricating machinery and other items from raw materials, as well as performing maintenance and repairs. They possess a wide array of technical and engineering skills that should be highlighted on their resume. Here are some skills to consider listing on a fabrication engineer’s resume:

- Design: Fabrication engineers have to be able to design and develop intricate blueprints and have the technical knowledge to use engineering software like CAD, CAM, and CNC.

- Fabrication: This involves cutting and joining materials to create machines and other items. Knowledge of welding, metalworking, plastics, and other similar processes is necessary.

- Maintenance and Repair: Fabrication engineers must have the ability to diagnose and repair problems with machinery and equipment.

- Project Management: Fabrication engineers must be able to plan, coordinate, and manage projects from start to finish.

- Safety: Fabrication engineers must be able to identify potential safety hazards and maintain a safe working environment.

- Communication Skills: They need to be able to effectively communicate with other team members and supervisors, as well as explain complex technical issues to non-technical people.

What skills should I put on my resume for Fabrication Engineer?

Fabrication engineers are responsible for the design, development, and production of various engineering projects, and their resumes need to reflect their skill set. If you are applying for a position as a Fabrication Engineer, here are some skills that should be included on your resume:

- Experience in fabrication engineering, including the ability to design, develop, and assemble complex components using a variety of materials

- Knowledge of industry standards and regulations

- Proficiency in computer-aided design (CAD) software

- Strong problem-solving, critical thinking, and decision-making skills

- Understanding of the fabrication process and related manufacturing techniques

- Ability to read and interpret blueprints and technical drawings

- Excellent communication and interpersonal skills

These are just some of the skills that are important for a successful career in fabrication engineering. Be sure to include as many relevant skills as possible, as employers will be looking for a well-rounded candidate who can handle the tasks associated with the position.

Key takeaways for an Fabrication Engineer resume

Fabrication Engineer resumes should be tailored specifically to the job you’re applying for, emphasizing your skills and experience that are most relevant to the job. While there are many things to consider, here are some key takeaways for crafting a successful Fabrication Engineer resume:

- Highlight your technical skills: Fabrication Engineers are expected to have expertise in a variety of materials and processes. Be sure to include a comprehensive list of your technical skills and highlight any certifications that you may have earned.

- Showcase your problem-solving skills: Fabrication Engineers are expected to be able to identify, troubleshoot, and fix problems that may arise during the fabrication process. Showcase any problem-solving experiences you have had in past positions.

- Demonstrate your project management abilities: Fabrication Engineers are often responsible for managing the timeline, budget, and resources for fabrication projects. Demonstrate your project management skills through your past experience, including any successful projects you may have completed.

- List your qualifications: Fabrication Engineers need to have an understanding of engineering principles and safety regulations, so be sure to list qualifications such as certifications and degrees in related fields.

- Detail any software experience: Many Fabrication Engineers must have experience with various software programs. Be sure to list any software you have experience with and any specific programs you have used in the past.

- Include any relevant industry experience: Fabrication Engineers need to have experience in the industry they are applying for to be successful. Detail any projects you may have worked on in the past and highlight any leadership roles you may have had.

By following these key takeaways, you can create a strong Fabrication Engineer resume that will help you stand out in a competitive job market.

Let us help you build

your Resume!

Make your resume more organized and attractive with our Resume Builder