Interviewing for a job in engineering can be a stressful time. If you are hoping to land an engineering job, it is important to be prepared for any questions that may come your way. One area of engineering that requires specific knowledge is Strength of Materials. If you are interviewing for a job focused on this topic, you will want to be sure that you are prepared to answer any Strength of Materials questions that you may be asked.

Strength of Materials is the study of how materials deform and react to various types of forces. It is a complex and interesting field of engineering that can be applied to many different industries. A basic understanding of this field is necessary in order to properly design and construct materials that can safely and effectively function under strain.

When interviewing for a job involving Strength of Materials, you will likely be asked a variety of questions. These may include questions about the principles of Strength of Materials, your knowledge of the topic, and examples of how you have used this knowledge in a practical setting. By having a good grasp of the fundamentals and being able to provide examples of your understanding, you will be able to prove that you have the required knowledge to be successful in the position.

To help you prepare for these interviews, we have compiled a list of Strength of Materials interview questions and answers. This list includes a variety of common questions that you may be asked during the interview, as well as ideas of how to answer them. By reading through these questions and answers, you will be able to gain a better understanding of the topics related to Strength of Materials and be better prepared for your interview.

Overview of Strength of Materials Interview Process

The Strength of Materials interview process is an important step in the hiring process for many engineering positions. It is important for potential employers to gain an understanding of a candidate’s knowledge and experience around the topics of strength of materials, material selection, and design of structures.

The process typically begins with a pre- screening and/or phone interview conducted by Human Resources personnel. During this discussion, the interviewer will discuss the candidate’s background, experience, and qualifications. They will ask questions related to the candidate’s experience and knowledge of Strength of Materials topics.

Following the initial phone interview, the candidate may be invited to attend an in- person interview with an engineer or engineering manager. This interview will generally consist of both technical and behavioral questions related to the candidate’s experience and knowledge in Strength of Materials.

Questions may cover topics such as the properties of materials, stress and strain, material selection, design of structures, and other related topics. The interviewer will often ask questions about the candidate’s experience in putting these principles into practice.

At the end of the interview, the candidate will likely be asked if they have any questions or comments. This is the candidate’s opportunity to ask any questions they may have about the company and the position, and to provide additional information about their background and experience.

The Strength of Materials interview process is an important part of the hiring process for many engineering roles. It is important for employers to understand a candidate’s level of experience and knowledge in this area in order to make an informed hiring decision.

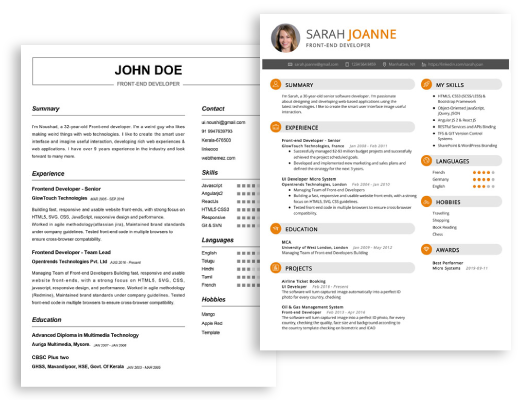

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

Be sure to check out our resume examples, resume templates, resume formats, cover letter examples, job description, and career advice pages for more helpful tips and advice.

Top 30 Strength of Materials Interview Questions and Answers

1. What is the definition of Strength of Materials?

Strength of Materials is the study of the mechanical behavior of materials under loading. It is the science behind the design and manufacture of structures, components, and machines. It deals with the behavior of materials such as steel, aluminum, and composites under various types of loads and stresses. The goal of strength of materials is to understand how materials interact with their environment and how they can be used to construct structures and components that can withstand specific loading and environmental conditions.

2. What are the two types of force that act on a material?

The two types of forces that act on a material are axial and shear forces. Axial forces are forces that are along the axis of the material, i.e. the direction of the load applied to the material. Shear forces are forces that act perpendicular to the axis of the material, i.e. the force that causes the material to deform or break.

3. What is the difference between tensile strength and compressive strength?

Tensile strength is the maximum stress (tension) a material can withstand before breaking. It is a measure of the material’s ability to resist being pulled apart. Compressive strength is the maximum stress (compression) a material can withstand before breaking. It is a measure of the material’s ability to resist being squeezed together.

4. What is the first law of thermodynamics?

The first law of thermodynamics is the conservation of energy. It states that energy can neither be created nor destroyed, only transferred from one form to another. This law is often referred to as the law of conservation of energy.

5. What is the difference between elasticity and plasticity?

Elasticity is the ability of a material to return to its original shape after being deformed. Plasticity is the ability of a material to permanently change its shape after being deformed.

6. What are the three types of stress?

The three types of stress are tensile, compressive, and shear stress. Tensile stress is the stress caused by a force pulling on the material. Compressive stress is the stress caused by a force pushing on the material. Shear stress is the stress caused by a force parallel to the surface of the material.

7. What is the difference between a beam and a column in terms of strength of materials?

Beams are structural members that are used to span an area and support a load. They are typically made from materials like steel or wood and can be continuous or discontinuous. Columns are structural members that are used to support a vertical load. They are typically made from materials such as concrete or steel and are usually continuous.

8. What is the difference between normal stress and shear stress?

Normal stress is the stress caused by a force acting along the perpendicular direction to the surface of a material. Shear stress is the stress caused by a force acting parallel to the surface of a material.

9. How do you calculate the elastic modulus of a material?

The elastic modulus of a material is calculated by dividing the applied stress by the resulting strain. The stress is the force applied to the material, and the strain is the amount the material deforms. The elastic modulus can then be used to calculate the strength of the material.

10. What is Young’s modulus?

Young’s modulus, also known as the modulus of elasticity, is a measure of the stiffness of a material when subjected to a tensile force. It is calculated by dividing the change in stress by the change in strain. The higher the Young’s modulus, the stiffer the material. This is an important property of materials used in engineering applications, as it determines the amount of stress that a material can withstand before it deforms.

11. What is a stress-strain curve?

A stress-strain curve is a graph that plots the amount of strain a material experiences as a function of the amount of stress applied to it. It can provide valuable information about a material’s mechanical properties, such as its stiffness, ductility, and strength. The shape of the curve can vary significantly depending on the material, and is useful for engineers when designing components.

12. What is elasticity?

Elasticity is the ability of a material to return to its original shape after being subjected to a load. It is determined by measuring the strain response of a material to an applied stress and comparing it to the original shape. Materials with high elasticity are able to return to their original shape after being subjected to a load, while materials with low elasticity are permanently deformed.

13. What is Hooke’s Law?

Hooke’s Law is a simple equation that states that the force applied to an object is proportional to the displacement of the object. This equation is important in the study of stress and strain, as it helps to illustrate how an object will deform when subjected to a load. It is an essential part of understanding how materials respond to applied forces and predicting how they will behave under different conditions.

14. What is a yield point?

A yield point is a point on a stress-strain curve at which a material begins to transition from elastic to plastic deformation. When a material is subjected to a load beyond this point, it will no longer return to its original shape and will instead be permanently deformed. The yield point is an important factor in determining the strength of a material and must be taken into consideration when designing components.

15. What are the three types of loading?

The three main types of loading that can be applied to a material are tension, compression, and shear. Tension is a pulling force that stretches a material, compression is a pushing force that compresses a material, and shear is a force that causes a material to deform in a sliding or rotating motion. These forces can act in combination to produce complex loading conditions that must be taken into account when designing components.

18. What is the difference between static and dynamic loading?

Static loading involves the application of a constant force to a material, which deforms it, but does not cause it to vibrate or move. Dynamic loading is the application of a force to a material that causes it to vibrate or move. Dynamic loading can cause materials to fail faster than static loading, as the vibrational forces can cause fatigue and damage over time.

19. What is the difference between tensile and compressive strength?

Tensile strength is a measure of how much force a material can withstand before it breaks when tension is applied. Compressive strength is a measure of how much force a material can withstand before it breaks when compression is applied. Tensile strength is typically higher than compressive strength for materials, as compression tends to cause more deformation than tension.

20. What is buckling?

Buckling is the process by which a structural member fails due to an applied compressive load. It occurs when the compressive load causes the material to become unstable, leading to a sudden collapse. Buckling is an important factor to consider when designing components, as it can cause sudden failure if the design is not strong enough to resist the loads that it will be subjected to.

21. What is the difference between a ductile and brittle material?

A ductile material is one that is able to deform plastically before failure, while a brittle material is one that fails suddenly without much deformation. Ductile materials are typically stronger than brittle materials, as they are able to absorb energy before failure. Brittle materials, on the other hand, are more prone to catastrophic failure and must be designed with this in mind.

22. What is the difference between a shear force and a moment?

A shear force is a type of force applied to a structural component that causes it to deform in one direction only, while a moment is a type of force applied to a structural component which causes it to deform in both directions. Specifically, a shear force is a type of force which is perpendicular to the surface of the component it is applied to and results in a deformation in the component, usually in the form of bending, shearing, or a combination of both. On the other hand, a moment is a type of force which causes a component to experience a twisting or rotating deformation.

23. What is the difference between stress and strain?

The basic difference between stress and strain is that stress is the force applied to a material in order to cause a deformation, while strain is the measurement of the resulting deformation of a material due to the force applied. Stress is a measure of the external force applied to a material, and it is expressed in units of force per unit area. Strain is a measure of the deformation of a material due to the external force, and it is expressed in terms of the ratio of the deformation to the original length of the material.

24. What is a uniform beam?

A uniform beam is a type of structural component which is subject to a uniform distribution of load along its length. The loads are typically uniform in magnitude and perpendicular to the beam’s longitudinal axis. It is important to note that the load is assumed to be constant along the entire length of the beam and is assumed to be a uniform load. The beam is also assumed to be straight, so the load is not distributed or varying in any way.

25. What is the difference between a point load and a distributed load?

A point load is a type of load which is applied to a structural component at a single point, while a distributed load is a type of load which is applied to a structural component along its entire length. Point loads are usually applied to a structural component in order to induce a certain amount of deformation, while distributed loads are applied to a structural component in order to induce a uniform deformation along the entire length of the component.

26. How is a column subject to buckling?

Columns are typically subject to buckling when an axial force is applied to them which is greater than the critical buckling load. This critical buckling load is the maximum axial force which the column can withstand before it begins to buckle and deform. This buckling can be prevented by strengthening the column, such as by adding additional supports or reinforcements, or by increasing the cross sectional area of the column.

27. What is the Modulus of Elasticity?

The Modulus of Elasticity, sometimes referred to as the Young’s Modulus, is a measure of a material’s ability to resist elastic deformation. It is defined as the ratio of the stress applied to a material divided by the strain caused by the stress. The Modulus of Elasticity is an important property of materials as it is used to calculate the stress-strain relationships of materials.

28. What is the difference between tension and compression?

Tension is the force applied to a material in order to cause it to stretch, while compression is the force applied to a material in order to cause it to shorten. Tension is typically applied to a material in order to produce a tensile strength test, while compression is typically applied to a material in order to produce a compressive strength test.

29. What is the difference between a static and dynamic load?

A static load is a type of force which is applied to a structural component, but remains constant over time, while a dynamic load is a type of force which is applied to a structural component and varies with time. Static loads typically occur as a result of gravity, while dynamic loads typically occur as a result of wind, vibration, or other types of motion.

30. What is the purpose of a deflection diagram?

A deflection diagram is a graphical representation of the deflection of a structural component due to an applied load. It is useful in determining the static and dynamic behavior of a structure, and is also used to determine the maximum allowable deflection of a structural component. Deflection diagrams are also used in order to design a structure for a particular purpose, such as ensuring that the structure is able to withstand certain loads without deforming too much.

Tips on Preparing for a Strength of Materials Interview

- Research the company and its products / services to be able to discuss how your strength of materials skills fit in.

- Prepare for questions about your experience in strength of materials and how it relates to the job.

- Learn about the major components of strength of materials and be able to describe them in detail.

- Prepare answers to common interview questions about your strengths and weaknesses.

- Be prepared to discuss specific engineering problems and how you have solved them.

- Practice and be ready to explain your approach to solving problems.

- Demonstrate your ability to think critically and problem solve.

- Practice explaining technical concepts in everyday language.

- Know the basics of stress, strain, and material properties.

- Have a portfolio ready to show your work in strength of materials.

- Be prepared to discuss how you work collaboratively with other team members.

- Demonstrate your knowledge of materials testing and analysis.

- Be prepared to talk about your experience using computer- aided engineering software.

- Be ready to discuss the different types of materials used in engineering.

- Be prepared to provide examples of how you have applied the principles of strength of materials.

Conclusion

This blog was created to provide a comprehensive list of strength of materials interview questions and answers. It explored the different types of questions that could be asked during an interview process for a strength of materials position. It also provided detailed answers to each of the questions, to help the interviewee prepare for their interview and answer the questions confidently and accurately. By understanding the topics covered in this blog, the interviewee should be able to tackle any questions asked in the strength of materials interview.