Electrical Machines are an important part of electrical engineering and are used in various applications. Interviews for electrical engineering jobs often require a good knowledge of electrical machines. If you are preparing for an interview to join a team of electrical engineers, it is important to have a thorough understanding of electrical machines.

This blog post will discuss a few important Electrical Machines Interview Questions & Answers that can help you in preparing for an electrical engineering job interview. We have compiled a list of questions that may be asked in an interview and provided answers that will help you understand the concepts and prepare for the interview in the best possible way.

The questions discussed in this blog post are designed to test your knowledge and understanding of the fundamentals of electrical machines. The questions range from basic concepts such as the working principle of motors and generators to more advanced topics such as the different types of electrical machines and their applications. We have also included answers to the questions so that you can easily understand the concepts discussed.

We hope that this blog post will help you in your preparation for an electrical engineering job interview. By understanding electrical machines better, you will be better prepared for any questions related to them. With the help of these Electrical Machines Interview Questions & Answers, you will be able to demonstrate your knowledge and understanding of electrical machines to the interviewer and make a good impression.

Overview of Electrical Machines Interview Process

The interview process for electrical machines positions typically involves three distinct stages: the initial application, the technical assessment, and the final interview. The initial application is usually carried out online and consists of a brief questionnaire that inquires about background information, relevant education, and experience. This is followed by a technical assessment that helps employers determine whether applicants possess sufficient technical skills to carry out the job requirements. This assessment can involve both written and practical tests to assess the applicant’s knowledge.

The final interview is the final stage of the process, where the applicant is invited to meet with the hiring manager or an engineer from the company. During this interview, the company will evaluate the candidate’s experience and ability to answer technical questions. The recruiter may also ask the applicant to demonstrate their problem- solving skills and knowledge of electrical machines. They may also be asked to provide a portfolio of their previous work.

At the end of this process, the company will make a final decision on whether or not to hire the applicant. If selected, the candidate will then be expected to begin work as soon as possible. It is important for applicants to prepare for the interview process by researching the company and the position in advance, so they are able to answer questions confidently and accurately.

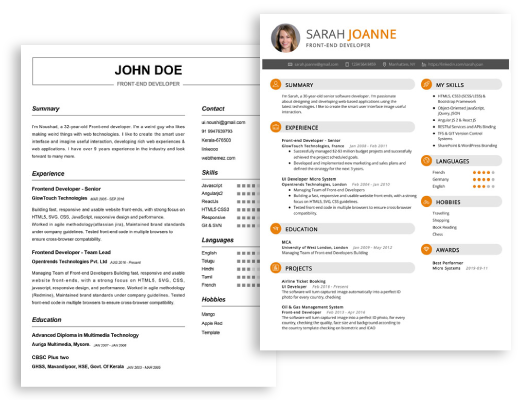

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

Be sure to check out our resume examples, resume templates, resume formats, cover letter examples, job description, and career advice pages for more helpful tips and advice.

Top 23 Electrical Machines Interview Questions and Answers

1. What is an electrical machine?

An electrical machine is any device that converts electrical energy into mechanical energy or vice versa. Examples of electrical machines include electric motors, generators, transformers, and alternators. They are used in a variety of applications, from powering machinery to providing electricity to homes and businesses.

2. What is the principle of operation of an electric motor?

The principle of operation of an electric motor is based on Faraday’s law of electromagnetic induction. This law states that when an electric current flows through a conductor, it will create an electromagnetic field. When this field interacts with a magnetic field, it will cause a force to be exerted on the conductor. This force is what causes the motor to rotate.

3. What are the different types of electric motors?

There are several different types of electric motors, including brushed and brushless DC motors, stepper motors, and AC induction motors. Brushless DC motors are the most common type of electric motor and are used in a variety of applications, from computers to automotive systems. Stepper motors are used in applications that require precise control, such as printing, robotics, and CNC machines. AC induction motors are used in many industrial applications, such as pumps and industrial machines.

4. How does an AC induction motor work?

An AC induction motor works by inducing a current in a conductor when it is exposed to a changing magnetic field. This current creates a torque that causes the motor to rotate. AC induction motors are commonly used in industrial applications and to power household appliances.

5. What is a transformer and how does it work?

A transformer is an electrical device that converts electrical energy from one form to another. It works by using an alternating current to induce a magnetic field, which then causes a current to be induced in a secondary coil. The current in the secondary coil is then used to power a motor or other device.

6. What is the difference between a generator and a motor?

A generator is an electrical device that converts mechanical energy into electrical energy, while a motor is an electrical device that converts electrical energy into mechanical energy. Generators are typically used to provide power to areas that lack access to the electrical grid, while motors are used to power a variety of applications, from machines to household appliances.

7. What is the purpose of an alternator?

The purpose of an alternator is to generate alternating current (AC). Alternators are used in a variety of applications, from automotive systems to power generators. They are typically used to provide electricity to areas that are not connected to the electrical grid.

8. What is the difference between a brushed and brushless motor?

A brushed motor is an electrical device that uses carbon brushes to conduct electricity to the motor, while a brushless motor uses magnets to conduct electricity. Brushed motors are typically cheaper and easier to maintain, while brushless motors are more efficient and provide more power.

9. What is the purpose of an inverter?

An inverter is an electrical device that converts direct current (DC) into alternating current (AC). It is used in a variety of applications, from powering electronic devices to providing electricity to homes and businesses.

10. What is a synchronous motor?

A synchronous motor is an electrical machine that uses magnets to generate a rotating magnetic field. This field interacts with the rotor of the motor, causing it to turn at a synchronized speed. Synchronous motors are used in a variety of applications, such as clocks, motors, and compressors.

11. What is the purpose of a servomotor?

A servomotor is an electrical device that is used to provide precise control of movement in a system. It is commonly used in robotics, automation, and other applications that require precise control of movement.

12. What is the difference between a linear motor and a rotary motor?

A linear motor is an electrical machine that produces a force in a straight line, while a rotary motor produces a force that turns in a circular motion. Linear motors are typically used in applications that require precise control of movement, such as robotics, while rotary motors are used in a variety of applications, from automotive systems to powering household appliances.

13. What is an induction generator?

An induction generator is an electrical machine that converts mechanical energy into electrical energy. It works by having a rotating magnetic field interact with a stationary coil, which induces a current in the coil. This current is then used to power a device or to provide electricity to an area.

14. What is the purpose of a power factor?

A power factor is a measure of how efficiently an electrical machine is using the power it is supplied with. It is calculated by dividing the power output of the machine (in watts) by the power input (in volts). The higher the power factor, the more efficient the machine is using the power it is supplied with.

15. What are the main factors that affect the efficiency of an electric motor?

The main factors that affect the efficiency of an electric motor include the design of the motor, the type of material used in the construction of the motor, the operating temperature, the load on the motor, and the frequency of the current supplied to the motor. Other factors, such as the type of lubrication used, the number of turns in the coils of the motor, and the type of insulation used in the motor can also affect the efficiency of an electric motor.

16. What are the different types of electrical machines?

The different types of electrical machines are AC machines, DC machines, synchronous machines, induction machines, and single-phase machines. AC machines are further divided into synchronous machines, induction machines, and single-phase machines. Synchronous machines are found in generators and are used for producing power. Induction machines are mainly used as motors as they have low starting torque. Single-phase machines are used for small loads such as domestic appliances. DC machines are mainly used as motors and are found in applications such as cranes and elevators.

17. What is the purpose of an electrical machine?

The purpose of an electrical machine is to convert electrical energy into mechanical energy or vice versa. It is mainly used in power generation, motors, and transformers. Power generation involves the conversion of electrical energy into mechanical energy that can be used to generate electricity. Motors are used to convert electrical energy into mechanical energy and can be found in applications such as cars and elevators. Transformers are used to convert electrical energy from one form to another.

18. What are the components of an electrical machine?

The components of an electrical machine include an armature, a field winding, and a commutator. The armature is the rotating part of the machine which is used to generate or absorb electrical energy. The field winding is used to produce a magnetic field which is used to interact with the armature. The commutator is used to reverse the direction of current in the armature.

19. What is the difference between AC and DC machines?

The main difference between AC and DC machines is that AC machines operate on alternating current, while DC machines operate on direct current. AC machines have variable speed and are used in applications such as power generation and motors. DC machines are mainly used as motors and are found in applications such as elevators and cranes.

20. How do electrical machines work?

Electrical machines work by converting electrical energy into mechanical energy or vice versa. AC machines use a combination of an armature and a field winding to generate a magnetic field which interacts with the armature to produce mechanical energy. DC machines use an armature, a field winding, and a commutator to generate a magnetic field which interacts with the armature to produce mechanical energy.

21. What are the advantages of electrical machines?

The advantages of electrical machines include their high efficiency, low maintenance cost, high speed, and affordability. They are also more reliable compared to other types of machines. They are also easy to install and can be used in a variety of applications.

22. What are the disadvantages of electrical machines?

The main disadvantage of electrical machines is that they require a constant supply of electricity to operate. They also require regular maintenance and can be affected by voltage fluctuations. They are also not suitable for high-temperature applications.

23. What are the safety precautions when using electrical machines?

When using electrical machines, it is important to take the necessary safety precautions to prevent accidents and injuries. It is important to read the manufacturer’s instructions before operating the machine. It is also important to ensure that the machine is installed in a properly grounded area. It is also important to wear protective clothing and equipment.

Tips on Preparing for a Electrical Machines Interview

- Research the company and its products or services. You should have a good understanding of the company you are interviewing with and what they do.

- Prepare questions to ask the interviewer. Prepare questions about the role, the team, and the company that show the interviewer that you are interested in and understand the job.

- Practice common electrical machines- related questions. Be prepared to answer questions about electrical machines, engineering principles, circuit analysis, electrical components, and more.

- Brush up on your math skills. Many electrical machines questions will involve calculations and equations, so make sure you are comfortable with basic mathematics and can solve basic equations.

- Review relevant industry news and trends. Being up- to- date on the latest developments in the electrical machines field can help you answer interview questions and hold conversations with the interviewer.

- Have your resume and portfolio ready. Bring a copy of your resume and a portfolio of your work to the interview.

- Prepare to talk about yourself. Have a prepared elevator speech that explains your experience and qualifications, and practice it in front of a mirror.

- Dress professionally. Make sure you look presentable on the day of the interview.

- Arrive early. Allow yourself plenty of time before the interview to get to the location and practice any last- minute preparations.

- Follow- up after the interview. Send a thank- you note to the interviewer to express your appreciation for their time.

Conclusion

Overall, the blog covers a wide range of electrical machine interview questions and answers. These questions provide a comprehensive overview of the types of questions you may be asked when interviewing for a job involving electrical machines. The answers provided can help you prepare for the interview, giving you the confidence to answer the questions and helping to ensure that you are best prepared for the job. Knowing the types of questions you might be asked and how to answer them can go a long way towards helping you land the perfect job.