An internal combustion engine (IC engine) is a type of engine commonly used in motor vehicles. It uses a combination of fuel and air to create a controlled combustion process inside a combustion chamber. The products of this combustion process then power the vehicle.

Interviewing for a role involving an IC engine can be daunting. There are many areas of knowledge that a potential candidate must have in order to succeed. This article will provide a comprehensive overview of the types of questions and answers one might expect to encounter in an IC engine related interview. In addition, this article will provide guidance on how to effectively answer these questions in order to make the best possible impression.

This article will cover a range of topics related to Internal Combustion Engines (IC engines). From basic concepts and terminology to more advanced concepts such as engine designs, engine components and troubleshooting techniques, this article will provide a comprehensive guide for anyone looking to succeed in an IC engine related interview.

Not only will this article provide all the questions and answers related to IC engine, but it will also provide helpful tips and advice on how to answer each question effectively. With this knowledge, any potential candidate will be well-equipped to ace their IC engine related interview and land the job of their dreams.

Overview of IC Engine Interview Process

The interview process for an internal combustion engine (ICE) is a rigorous process that requires preparation and knowledge. Before the interview, candidates should research the company, the role and its requirements, the industry, and the key technologies. During the interview, the interviewer will typically ask questions related to the candidate’s experience, qualifications, and skills. They will also likely ask about their familiarity with the ICE technology, their understanding of the company’s goals and strategies, and their ability to work as a team.

The interview process typically begins with an introductory phone call to assess the candidate’s basic qualifications. After that, if the initial assessment is successful, the interview process will move forward to a face- to- face meeting. During this meeting, the interviewer will likely ask questions related to the candidate’s experience, qualifications, and skills, as well as questions related to the ICE technology. It is important for the candidate to answer these questions honestly and factually. The interviewer will also likely ask questions related to the company’s goals and strategies and the candidate’s ability to work as a team.

The next step in the interview process is the technical assessment. Here, the candidate will be asked to demonstrate their knowledge of the ICE technology. This may take the form of a hands- on demonstration, a written test, or a combination of both. The interviewer will use this assessment to evaluate the candidate’s level of knowledge and determine if they have the necessary skills to succeed in the role.

Finally, the interview process may also include a personality assessment. This is done to ensure that the candidate is a good fit for the team and will work well with the company culture. In the end, the interviewer will make a decision based on all of the information gathered during the interview process.

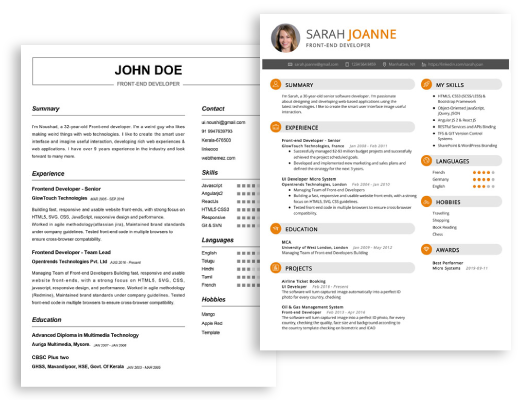

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

Be sure to check out our resume examples, resume templates, resume formats, cover letter examples, job description, and career advice pages for more helpful tips and advice.

Top 20 IC Engine Interview Questions and Answers

1. What is an IC Engine?

An Internal Combustion (IC) engine is a type of engine that generates mechanical energy from the combustion of a fuel source, often gasoline or diesel. This combustible fuel is ignited by a spark or a compression of air and fuel. The combustion process creates a rapid expansion of burning gases, which drive a piston and crankshaft to create rotational motion. This rotational motion is then used to drive a variety of mechanical components, such as an engine’s crankshaft, camshafts, and other components.

2. How does an IC Engine work?

An IC engine works by converting chemical energy into mechanical energy. The fuel is usually a combustible liquid or gas such as gasoline, diesel, or propane. When the fuel is introduced into the engine, it is combined with air and compressed. This compression increases the temperature and pressure of the fuel/air mixture. When the fuel/air mixture is ignited, it expands rapidly, driving the piston down and turning the crankshaft. This turning motion is then used to power the various components within the engine, such as the crankshaft, camshafts, and other components.

3. What are the main components of an IC Engine?

The main components of an IC engine are the cylinders, the valves, the piston, the connecting rod, the crankshaft, the camshaft, the fuel injection system, and the intake and exhaust manifolds. The cylinders are where the combustion of the fuel/air mixture occurs and the piston is connected to the crankshaft via the connecting rod. The camshaft is responsible for opening and closing the valves at the proper times during the 4-stroke cycle. The fuel injection system is responsible for delivering the correct amount of fuel/air mixture to the cylinders. Finally, the intake and exhaust manifolds are responsible for allowing the exhaust gases to escape and the intake air to enter the cylinders.

4. What is the 4-stroke cycle?

The 4-stroke cycle is the order of events that occur in a typical Internal Combustion Engine. It consists of four distinct strokes: Intake, Compression, Power and Exhaust. During the Intake stroke, the intake valve opens and the piston moves down, drawing in the fuel/air mixture. During the Compression stroke, the intake valve closes and the piston moves up, compressing the fuel/air mixture. During the Power stroke, the spark plug ignites the fuel/air mixture and the piston moves down, creating power. Finally, during the Exhaust stroke, the exhaust valve opens and the piston moves up, pushing the exhaust gases out of the cylinders.

5. What is the difference between a gasoline engine and a diesel engine?

The main difference between a gasoline engine and a diesel engine is the way in which the fuel/air mixture is ignited. In a gasoline engine, the fuel/air mixture is ignited by a spark from the spark plug. In a diesel engine, the fuel/air mixture is ignited by the high temperature and pressure created by compressing the fuel/air mixture. Diesel engines are more efficient than gasoline engines and are usually used in applications where efficiency is important, such as in trucks and large machinery.

6. What is the difference between a two-stroke and a four-stroke engine?

The main difference between a two-stroke engine and a four-stroke engine is the number of strokes it takes to complete one cycle. In a two-stroke engine, only two strokes are needed to complete one cycle, while in a four-stroke engine, four strokes are needed to complete one cycle. Additionally, the timing of the fuel/air mixture ignition is different for each type of engine. In a two-stroke engine, the fuel/air mixture is ignited every time the piston moves in either direction, while in a four-stroke engine, the fuel/air mixture is only ignited on the power stroke.

7. What is the maximum speed an IC Engine can reach?

The maximum speed an IC engine can reach is largely determined by the engine design and the fuel used. Generally speaking, gasoline engines are designed to reach speeds of up to 8,000 rpm, while diesel engines are designed to reach speeds of up to 4,000 rpm. However, some high-performance engines can reach speeds upwards of 10,000 rpm.

8. What are the advantages of using an IC Engine?

The main advantages of using an IC engine are that they are relatively simple and inexpensive to build, they are highly efficient, and they can be used in a wide variety of applications. Additionally, IC engines are capable of producing high levels of torque, which is necessary for powering heavy machinery and vehicles.

9. What are the disadvantages of using an IC Engine?

The main disadvantages of using an IC engine are that they are relatively noisy and produce large amounts of pollutants. Additionally, IC engines are not as efficient as other types of engines, such as electric motors, and they require regular maintenance.

10. What is a turbocharger?

A turbocharger is a device that is used to increase the power output of an IC engine. The turbocharger forces more air into the combustion chamber, which increases the power output of the engine. Turbochargers are often used in high-performance vehicles and can greatly increase the power output of an IC engine.

11. What are the types of IC engines?

There are two main types of IC engines: reciprocating and rotary. Reciprocating engines use the up-and-down movement of the pistons in order to create the power to drive the vehicle. This type of engine is commonly found in automobiles and is typically powered by gasoline or diesel. Rotary engines use a rotary motion to generate power and are often found in helicopters and motorcycles. This type of engine is usually powered by gasoline, but some newer versions are powered by diesel fuel as well.

12. What is the Otto cycle?

The Otto cycle is a thermodynamic cycle named after the German engineer Nikolaus Otto. It is a four-stroke cycle where the piston goes through two strokes of compression and two of expansion. During the compression stroke, the fuel-air mixture is compressed to a high pressure and temperature. During the expansion stroke, this high-pressure fuel-air mixture is ignited and expands rapidly, providing the power to drive the vehicle. This cycle is the most commonly used cycle in modern automobiles.

13. What is an internal combustion engine?

An internal combustion engine is an engine that uses the combustion of fuel and air to generate power. This power is then used to drive a vehicle, power machinery, or other applications. The combustion of fuel and air produces high pressure and temperature gases that are then pushed out of the engine cylinders. This produces a force that is then used to move a crankshaft and turn the wheels of the vehicle.

14. How does an internal combustion engine work?

An internal combustion engine works by burning a fuel and air mixture inside the cylinders. The piston within the cylinder is then forced down, producing a force that is then used to drive a crankshaft. The crankshaft then turns the vehicle’s wheels and moves the vehicle forward. The force produced by the combustion is also used to power accessories such as air conditioning or power steering.

15. What are the different types of internal combustion engines?

The main types of internal combustion engines are spark-ignition engines and compression-ignition engines. Spark-ignition engines use spark plugs to ignite the air and fuel mixture, while compression-ignition engines use fuel injection and high compression ratio to ignite the air and fuel mixture.

16. What are the components of an internal combustion engine?

The main components of an internal combustion engine are the cylinders, pistons, crankshaft, valves, fuel system, exhaust system, and ignition system. The cylinders house the pistons, which move up and down to drive the crankshaft and produce power. The valves regulate the intake and exhaust of air and fuel into and out of the cylinders, while the fuel system feeds the fuel to the engine. The exhaust system carries away the exhaust gases, and the ignition system ignites the air and fuel mixture in the cylinders.

17. What are the advantages of an internal combustion engine?

The main advantages of an internal combustion engine are that they are efficient, reliable, and powerful. They are efficient because they generate a lot of power per unit of fuel burned, and they are reliable because they require minimal maintenance. Additionally, they are powerful and can produce high amounts of torque and power.

18. What are the disadvantages of an internal combustion engine?

One of the main disadvantages of an internal combustion engine is that they produce emissions, which are harmful to the environment. Additionally, they are noisy and require regular maintenance. Furthermore, they are becoming less cost-effective due to the increasing cost of fuel.

19. What is the purpose of the ignition system?

The purpose of the ignition system is to ignite the air and fuel mixture in the cylinders. This is done with an electric spark, which is produced by the spark plugs. The spark plugs ignite the air and fuel mixture, which then produces a force that drives the crankshaft and turns the vehicle’s wheels.

20. What is the function of the crankshaft?

The function of the crankshaft is to convert the linear motion of the pistons into rotational motion. The crankshaft is connected to the pistons via connecting rods, and is then connected to the vehicle’s wheels. The motion of the pistons is then transferred to the crankshaft, which turns the wheels of the vehicle and drives it forward.

Tips on Preparing for a IC Engine Interview

- Research the company and their products: Find out as much as possible about the company and its products, so you can demonstrate your knowledge when asked questions about the company.

- Practice answering common IC engine interview questions: Review common IC engine interview questions and practice your answers aloud.

- Brush up on your technical knowledge: Make sure you have a solid understanding of IC engine technology, including various components, design principles, and operation.

- Prepare a portfolio of your work: Gather relevant documentation, drawings, and technical papers that showcase your experience and skills.

- Prepare questions to ask the interviewer: Have a few thoughtful questions prepared that demonstrate your knowledge and interest in the position.

- Dress professionally: Make sure you’re dressed in professional attire that’s appropriate for the position.

- Arrive early: Give yourself plenty of time to get to the interview location, so you can be calm and focused.

- Remain positive: Stay positive and enthusiastic during the interview, as this can help you make a good impression.

- Be prepared to discuss challenges: Be prepared to discuss challenges you have faced and how you overcame them.

- Be honest: Be honest and direct in your answers to ensure the interviewer knows where you stand.

- Follow up: Send a thank- you note to the interviewer after the interview, expressing your interest in the position and thanking them for their time.

Conclusion

This article has provided a comprehensive list of IC engine interview questions and answers, which can be used to prepare and assess the knowledge of any candidate when interviewing for positions related to internal combustion engines. The article has covered a range of topics, from basic concepts and principles to more technical components, such as fuel injection and exhaust systems. Additionally, it has outlined the differences between gasoline and diesel engines, as well as the various types of fuels available for internal combustion engines. By understanding the content of this article, candidates for a job related to internal combustion engines should be better prepared to face an interview.