Instrumentation is an important area of study and work in engineering, science, and industry. Instrumentation is the process of measuring, controlling, and monitoring physical devices, such as temperature, pressure, humidity, level, flow, etc. Instrumentation engineers are responsible for designing and installing instruments in the various systems, and for ensuring that the instruments are accurate and reliable.

Interviewing for an instrumentation position can be a daunting task. It is important to be well prepared for any and all questions that may be asked, as well as any challenges that may arise during the interview process. To help individuals prepare for their instrumentation interviews, we have compiled a comprehensive list of instrumentation interview questions and answers. Our comprehensive list of interview questions covers a variety of topics, from electrical engineering and automation to instrumentation and control systems.

This blog post provides a comprehensive list of instrumentation interview questions and answers. We have included questions and answers related to instrumentation engineering, automation and control systems, electrical engineering, and more. We have also included a list of tips and advice on how to best prepare for an instrumentation interview. With the help of this blog post, you can feel confident and prepared when going into your next instrumentation interview.

Overview of Instrumentation Interview Process

The instrumentation interview process is an important step in the hiring process for any organization that operates complex machinery or equipment. This process typically involves a combination of screening and psychometric tests to evaluate the skills and knowledge of potential candidates. Depending on the complexity and scope of the role, the instrumentation interview process may also incorporate role- specific assessments, such as technical simulations or hands- on exercises.

The instrumentation interview typically begins with a pre- screening process in which the hiring manager gathers basic information about the candidate, such as their educational background, employment history, and relevant skills. This initial step is important for assessing the candidate’s suitability for the job and determining whether they have the necessary qualifications and experience to fulfill the role.

The next step in the instrumentation interview process is a psychometric assessment, which is designed to evaluate the candidate’s problem- solving skills and cognitive abilities. This is typically done with a series of questions and exercises that are tailored to the specific job and industry. For example, a psychometric assessment for a mechanical engineering position may include questions about mechanical concepts, concepts related to electricity and electronics, and problem- solving tasks.

Finally, the instrumentation interview process may also include a technical assessment. This typically involves a hands- on demonstration of the candidate’s ability to operate and troubleshoot various machines and equipment. The assessment may also include simulations or other exercises that demonstrate the candidate’s ability to interpret technical diagrams, read and follow instructions, and apply their knowledge to solve problems.

By incorporating a combination of screening, psychometric, and technical assessments, the instrumentation interview process provides organizations with a comprehensive evaluation of potential candidates. This helps to ensure that the hiring organization finds the most qualified and capable person for the role, and minimizes the risk of making a hiring mistake.

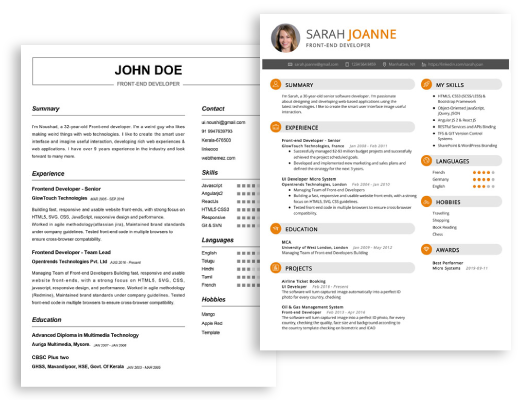

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

Be sure to check out our resume examples, resume templates, resume formats, cover letter examples, job description, and career advice pages for more helpful tips and advice.

Top 18 Instrumentation Interview Questions and Answers

1. What is Instrumentation?

Instrumentation is the process of creating, measuring, and controlling the physical entities of a system. It is the use of instruments, such as sensors, transducers, and controllers, to measure, monitor, and control the operation of a system. Instrumentation can be used for a variety of purposes, such as measuring temperature, pressure, and flow, or controlling motors and valves. Instrumentation is an important part of many industrial processes, and can be used to improve safety, efficiency, and reliability.

2. What are the main types of instruments used in instrumentation?

The main types of instruments used in instrumentation include sensors, transducers, and controllers. Sensors are used to measure physical parameters such as temperature, pressure, and flow. Transducers convert sensed physical parameters into electrical signals, which can then be processed by controllers. Controllers are used to adjust the operation of a system based on the measured values.

3. What is a signal conditioner?

A signal conditioner is a device used to convert an input signal into an appropriate form for processing or control. Signal conditioners are used to convert signals from sensors into a usable form, such as a voltage or a current signal, for further processing. They are used to isolate, amplify, filter, and convert signals to make them compatible with the control system.

4. What is a PID controller?

A PID (Proportional-Integral-Derivative) controller is a type of controller that uses a feedback loop to control a system. The PID controller adjusts the output of a system based on its input, using a combination of proportional, integral, and derivative terms. PID controllers are commonly used for controlling temperature, pressure, flow, and other parameters in industrial processes.

5. What is an SCADA system?

SCADA stands for Supervisory Control and Data Acquisition. It is a type of computer system used to control and monitor industrial processes. SCADA systems consist of a number of components, including sensors, transducers, controllers, and HMI (Human Machine Interface). SCADA systems are used to monitor and control various industrial processes, such as power generation, water supply, and manufacturing.

6. What is a distributed control system (DCS)?

A distributed control system (DCS) is a computer system used for the automated control of industrial processes. DCSs consist of multiple components, including sensors, transducers, controllers, and communication networks. DCSs are used to monitor and control complex processes such as power generation, water supply, and manufacturing.

7. What are the different types of sensors used in instrumentation?

The different types of sensors used in instrumentation include temperature sensors, pressure sensors, flow sensors, level sensors, position sensors, and proximity sensors. Temperature sensors measure temperature, pressure sensors measure pressure, flow sensors measure flow rate, level sensors measure liquid level, position sensors measure position, and proximity sensors measure the distance between objects.

8. What is a transducer?

A transducer is a device used to convert one form of energy into another. Transducers are used to convert signals from sensors into electrical signals that can be processed by controllers. Transducers can also be used to convert electrical signals into physical outputs, such as pressure or force.

9. What is a transmitter?

A transmitter is a device used to transmit signals from one point to another. Transmitters are used to send signals from sensors to controllers, or from controllers to actuators. Transmitters can be used to transmit signals over long distances, or through different mediums, such as air, water, or cable.

10. What is an actuator?

An actuator is a device used to convert electrical signals into physical outputs. Actuators are commonly used to control motors, valves, and other mechanical devices. Actuators are controlled by controllers, which use signals from sensors and transducers to adjust their outputs.

11. What is a control system?

A control system is a system used to control the operation of a process. Control systems consist of sensors, transducers, controllers, and actuators. Sensors measure physical parameters of a system, transducers convert those parameters into electrical signals, controllers process the signals and adjust the outputs of actuators, and actuators convert the electrical signals into physical outputs.

12. What is a process control loop?

A process control loop is a closed-loop system used to control the operation of a process. The process control loop consists of a sensor, a transducer, a controller, and an actuator. The sensor measures the physical parameters of the system, the transducer converts those parameters into electrical signals, the controller processes the signals and adjusts the outputs of the actuator, and the actuator converts the electrical signals into physical outputs.

13. What is a calibration?

A calibration is the process of adjusting the sensitivity or output of an instrument to ensure it is accurately measuring the physical parameter it is designed to measure. Calibration is an important part of instrumentation and is necessary to ensure accuracy and reliability.

14. What is a programmable logic controller (PLC)?

A programmable logic controller (PLC) is a type of computer used to control industrial processes. PLCs are programmed with a set of instructions that allow them to monitor inputs, process data, and control outputs. PLCs are used in many industrial processes and can be used to automate and improve the performance of a system.

15. What is a data acquisition system?

A data acquisition system (DAQ) is a system used to collect and analyze data from sensors and other sources. DAQ systems consist of software, hardware, and communication networks, and are used to monitor and control industrial processes. DAQ systems are used to collect data from multiple sources, process the data, and store it for later analysis.

16. What is an interface?

An interface is a device used to connect two systems together. An interface translates the signals from one system into a form that the other system can understand. Interfaces are commonly used to connect sensors to controllers, controllers to actuators, and computers to controllers.

17. What is a safety system?

A safety system is a system used to protect personnel and equipment from potential hazards. Safety systems consist of sensors, transducers, alarms, and other components that are used to detect and respond to potential hazards. Safety systems are used to protect personnel and equipment from fire, explosion, and other dangerous situations.

18. What is a Human Machine Interface (HMI)?

A Human Machine Interface (HMI) is a user interface that allows users to interact with a system. HMIs consist of graphical user interfaces, such as touchscreens, keyboards, and joysticks, and are used to control and monitor industrial processes. HMIs are used to provide users with an intuitive way to interact with a system and can improve safety, efficiency, and reliability.

Tips on Preparing for a Instrumentation Interview

- Research the company and the job you are interviewing for. Be familiar with their products, services, and any current news about the company.

- Know what you want to say in response to common interview questions. Prepare answers to common questions such as those related to your experience and skills.

- Practice your answers to questions. Rehearse your answers to questions in front of a mirror or with a friend to reduce nervousness on the day of the interview.

- Dress professionally and appropriately. Choose an outfit that is suitable for the work environment and industry.

- Bring extra copies of your resume and other documents. Have a portfolio of your relevant certifications and qualifications to show your interviewer.

- Arrive a few minutes early to the interview. This will help you to remain calm and collected before the interview starts.

- Be prepared to ask questions and use the opportunity to get a better understanding of the company and the job.

- Be sure to maintain good eye contact and posture throughout the interview. Show the interviewer that you are confident in yourself and your abilities.

- Be honest about your experience and don’t embellish. Be aware that the interviewer may verify what you say.

- Demonstrate your interest in the job and company. This can be done by talking about how you can use your skills and experience to benefit the company as well as asking intelligent questions.

- Listen closely to the interviewer and take notes if necessary. This will help you to give the best possible responses.

- Send a thank you note after the interview. This will show your appreciation and help the interviewer remember you.

- Take time to reflect on the interview and think about how you could have done better. Use this time to develop strategies to improve your performance in future interviews.

- Connect with the interviewer on LinkedIn. This

Conclusion

In conclusion, instrumentation is an important field of engineering and a necessary part of many industries. By familiarizing yourself with the most common interview questions and being prepared to articulate thoughtful answers, you will be in a great position to ace your interview and land that job. It is also important to stay up to date on developments in the instrumentation field to ensure your knowledge and skills remain relevant. Hopefully the information provided in this blog has been helpful in preparing you for your instrumentation interview. Good luck!