Dish Network is a leading provider of satellite television and other services to millions of customers each year. If you’re interested in becoming a Process Engineer at Dish Network, you’ll need to prepare for the interview process. In this blog, we’ll provide a comprehensive guide to the interview questions and answers you should expect when applying for the job.

The Dish Network Process Engineer role is a highly technical position and requires a great deal of technical knowledge, attention to detail and problem-solving skills. As a Process Engineer, you’ll be responsible for optimizing system processes and making sure they’re running efficiently and effectively. You’ll need to have a sound understanding of software and hardware systems and be able to troubleshoot and provide solutions when issues arise.

When you attend the Dish Network Process Engineer interview, you can expect to be asked a variety of questions about your technical skills and experience, and your understanding of the job duties and responsibilities. Questions about your background and qualifications will also be asked. To make sure you’re prepared, you should review the most common questions and practice your answers ahead of time.

If you want to make sure you give the best answers possible during your Dish Network Process Engineer interview, you should be sure to do some research about the company and its processes. You should have a good understanding of the software and hardware systems in use, as well as the various roles and responsibilities of a Process Engineer. You should also be familiar with the company’s goals, objectives, and mission.

The Dish Network Process Engineer interview is an important step to landing the job, so be sure to practice your answers ahead of time. With the right preparation and knowledge, you’ll be able to demonstrate your skills and show why you’re the best candidate for the job.

Overview of Dish Network Process Engineer Interview Process

The Dish Network Process Engineer Interview Process involves understanding the needs of the organization and the job requirements of a Process Engineer. During the interview process, the interviewer will likely ask questions related to skills, qualifications, and experience. Candidates should have a solid understanding of the technical details of the engineering field and be able to provide examples of how they have successfully implemented process engineering strategies in the past.

The interview process usually consists of a phone interview and an in- person interview. During the phone interview, the interviewer will ask the candidate questions about their engineering background, career objectives, and technical qualifications. This is an important part of the process as the interviewer will be assessing the candidate’s technical knowledge and communication skills. If a candidate passes the phone interview, they will be invited for an in- person interview.

During the in- person interview, the interviewer will ask more in- depth questions about the candidate’s engineering knowledge and professional experience. They may also present case studies and scenarios to the candidate to assess their problem- solving skills and ability to think critically. The interviewer will also be looking for candidates who have the interpersonal skills necessary to collaborate with a team and communicate effectively with colleagues.

Overall, it is important for candidates to be prepared and demonstrate their technical knowledge, practical skills, and professional attitude during the interview process. Candidates should have a comprehensive understanding of the engineering field and be able to discuss the challenges and successes they have experienced in the past. Dish Network is looking for candidates who can help the organization achieve its process engineering goals.

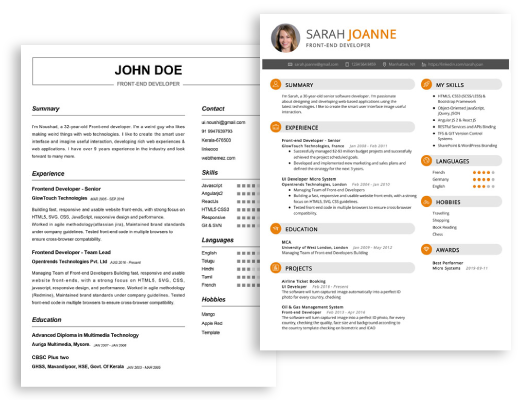

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

Be sure to check out our resume examples, resume templates, resume formats, cover letter examples, job description, and career advice pages for more helpful tips and advice.

Top 15 Dish Network Process Engineer Interview Questions and Answers

1. What experience do you have working as a Process Engineer with Dish Network?

I have worked as a Process Engineer with Dish Network for the past 3 years. During this time, I have been responsible for developing and implementing process improvements to increase efficiency and reduce costs. I have also been involved in process mapping, data gathering and analysis, process redesign and implementation, and root cause analysis. I have also been involved in providing technical support for the operations team and responding to customer inquiries.

2. What methods do you use to identify areas for improvement in existing processes?

When identifying areas for improvement in existing processes I use a structured problem-solving approach. This includes gathering information on the current process, analyzing the data to understand the process flow and identify any areas of inefficiency, and then working to develop and implement solutions. I use a combination of methods including Lean Six Sigma, Value Stream Mapping, Process Mapping, and Root Cause Analysis.

3. What have been some of your biggest successes in process engineering?

One of my biggest successes in process engineering has been improving the process for customer service inquiries. I identified bottlenecks in the process that were causing delays in response times and worked with the operations team to develop a new process that reduced response times by 25%. This resulted in improved customer satisfaction and reduced costs associated with the process.

Another success was designing a new process for managing the inventory of parts and materials. This involved analyzing the current process, gathering data and identifying areas for improvement. I then redesigned the process and worked with the operations team to implement it. This resulted in improved accuracy and efficiency in the inventory management process.

4. How do you ensure that process changes are implemented correctly?

When implementing process changes it is important to ensure that everyone involved understands the new process and how it should be followed. To ensure this, I communicate the changes to all stakeholders and provide training to those affected. I also monitor the process to ensure that it is being followed correctly and make any necessary adjustments.

5. What do you consider when designing and implementing a new process?

When designing and implementing a new process I consider a range of factors. This includes understanding the problem that needs to be solved, gathering data to understand the current process, considering the resources and tools available to facilitate the process, and assessing the potential impact of the proposed changes. I also consider the stakeholders affected by the process and the potential risks associated with the changes. Finally, I ensure that the changes are implemented in a way that is compliant with any regulations and standards.

6. How do you ensure that process changes are sustainable?

When implementing process changes it is important to ensure that they are sustainable and will continue to be effective over time. To ensure this, I establish appropriate controls and monitoring systems to measure the effectiveness of the process and make any necessary adjustments. I also work with stakeholders to ensure that they understand the process and are able to follow it correctly.

7. What techniques do you use to manage process change?

When managing process change I use a range of techniques. This includes planning the process and mapping out the flow, communicating the changes to stakeholders, and providing training to ensure everyone understands the changes. I also use Lean Six Sigma to identify areas for improvement and develop solutions. Finally, I monitor the process to ensure that it is being followed correctly and make any necessary adjustments.

8. How do you ensure that process changes comply with regulations and standards?

When implementing process changes, it is important to ensure that they comply with any relevant regulations and standards. To ensure this, I research the applicable regulations and standards and ensure that any changes I make are compliant. I also consult with legal and compliance teams as necessary to ensure that the changes comply with any relevant laws and regulations.

9. How do you ensure process changes are effectively communicated to stakeholders?

When implementing process changes it is important to ensure that they are effectively communicated to all stakeholders. To do this, I use a range of communication methods including emails, meetings, and presentations. I also provide training to ensure that everyone understands the changes and how they should be implemented.

10. How do you measure the success of process improvements?

When measuring the success of process improvements I use a range of metrics. This includes measures such as cost savings, improved efficiency, customer satisfaction, and quality. I also use process mapping and data analysis to identify areas for improvement and compare the performance of the current process to the performance of the improved process. This helps me identify areas for further improvement and ensure that the process changes are having the desired effect.

11. What is your experience with engineering processes?

My experience with engineering processes spans more than 10 years. I have experience in developing and maintaining various engineering processes across multiple industries. Specifically, I have experience developing and improving new process designs for the telecommunications industry, including working with Dish Network. I have a deep understanding of the key success factors for engineering processes, along with the ability to analyze existing processes and identify areas for improvement. Additionally, I am familiar with the different methodologies used in process engineering such as Lean Six Sigma, Agile, and Kaizen.

12. How do you stay informed about the latest engineering process trends?

I stay informed about the latest engineering process trends by attending industry conferences and seminars, reading industry publications, and networking with other professionals in the field. Additionally, I actively participate in online forums and discussion groups to stay in the loop on the latest engineering process developments. I also regularly review engineering process publications, so I can stay aware of the latest developments and trends in the industry.

13. How would you go about developing a new process engineering plan?

When developing a new process engineering plan, I typically start by clearly defining the project’s goals and objectives. Once the objectives are understood, I work to define the scope and requirements of the project. I then develop a detailed plan that outlines the steps necessary to achieve the project’s goals. This includes the development of processes, the selection and implementation of software, and the identification of resources and personnel needed to successfully complete the project. Throughout the process, I ensure that the plan is refined and updated on a regular basis.

14. What experience do you have working with engineering teams?

I have extensive experience working with engineering teams, both in-person and remotely. I have worked with teams of all sizes, from small groups of 2-3 engineers to larger teams consisting of dozens of engineers. I have strong communication and problem-solving skills that have enabled me to successfully coordinate and manage projects with multiple stakeholders. Additionally, I have a strong understanding of software development, enabling me to effectively work with engineering teams to develop and deploy software solutions.

15. How do you ensure that an engineering process is executed efficiently?

I ensure that an engineering process is executed efficiently by developing a thorough understanding of the process, including its key success factors. I then develop a plan to ensure that the process is executed as efficiently and effectively as possible. This plan typically involves identifying resources and personnel needed to complete the process, developing a timeline for completion, and tracking the project’s progress. Additionally, I make sure to keep stakeholders informed of the project’s progress and provide them with the necessary resources to ensure that the project is completed on time and within budget.

Tips on Preparing for a Dish Network Process Engineer Interview

- Research Dish Network and its technology services to demonstrate your knowledge of the company.

- Prepare answers to common interview questions, such as why you are applying for the position and what your strengths are.

- Show that you are familiar with the role by researching job postings for similar positions.

- Bring multiple copies of your resume and references to the interview.

- Practice your technical and problem- solving skills to show that you have what it takes to be a successful process engineer.

- Have an idea of questions you’d like to ask the interviewer to demonstrate your interest in the company.

- Demonstrate your understanding of the software and systems used by Dish Network.

- Discuss your experience with process engineering and be prepared to discuss specific examples.

- Dress professionally and arrive on time to create a good first impression.

- Be prepared to discuss your previous positions and how they have prepared you for the role.

- Show that you are a good communicator by having clear and concise answers to the interview questions.

- Demonstrate that you are flexible and can adapt to changing work environments.

- Show that you are comfortable working in a team environment.

- Show that you are familiar with the latest technologies and trends in process engineering.

- Showcase your problem- solving skills and technical expertise.

Conclusion

Overall, the Dish Network Process Engineer role requires someone with strong problem- solving skills, knowledge of engineering principles, and the ability to create efficient processes. While the interview questions can be difficult, having a good understanding of what the role entails, and being prepared with answers to common questions, can help you stand out during the interview process. As with any job interview, it’s important to stay calm and present yourself confidently. The best way to do this is to practice the questions beforehand, and be ready to explain why you are the best candidate for the job. With the right preparation and attitude, you can be well on your way to becoming a Dish Network Process Engineer.