Writing a QC Welding Inspector resume can be daunting and time consuming. After all, your resume is a document that outlines your professional experience and qualifications, and serves as a representation of who you are as a job candidate. It is essential to craft a resume that highlights your expertise and showcases your technical and professional knowledge. This guide will provide you with tips and examples on how to create an effective and impressive QC Welding Inspector resume that will help you land the job you desire.

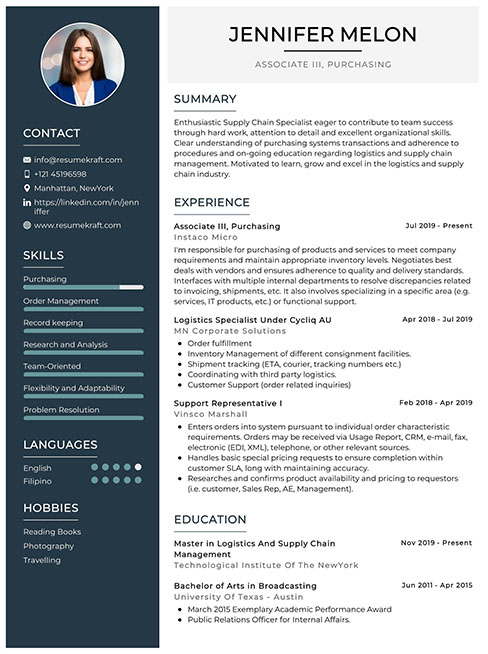

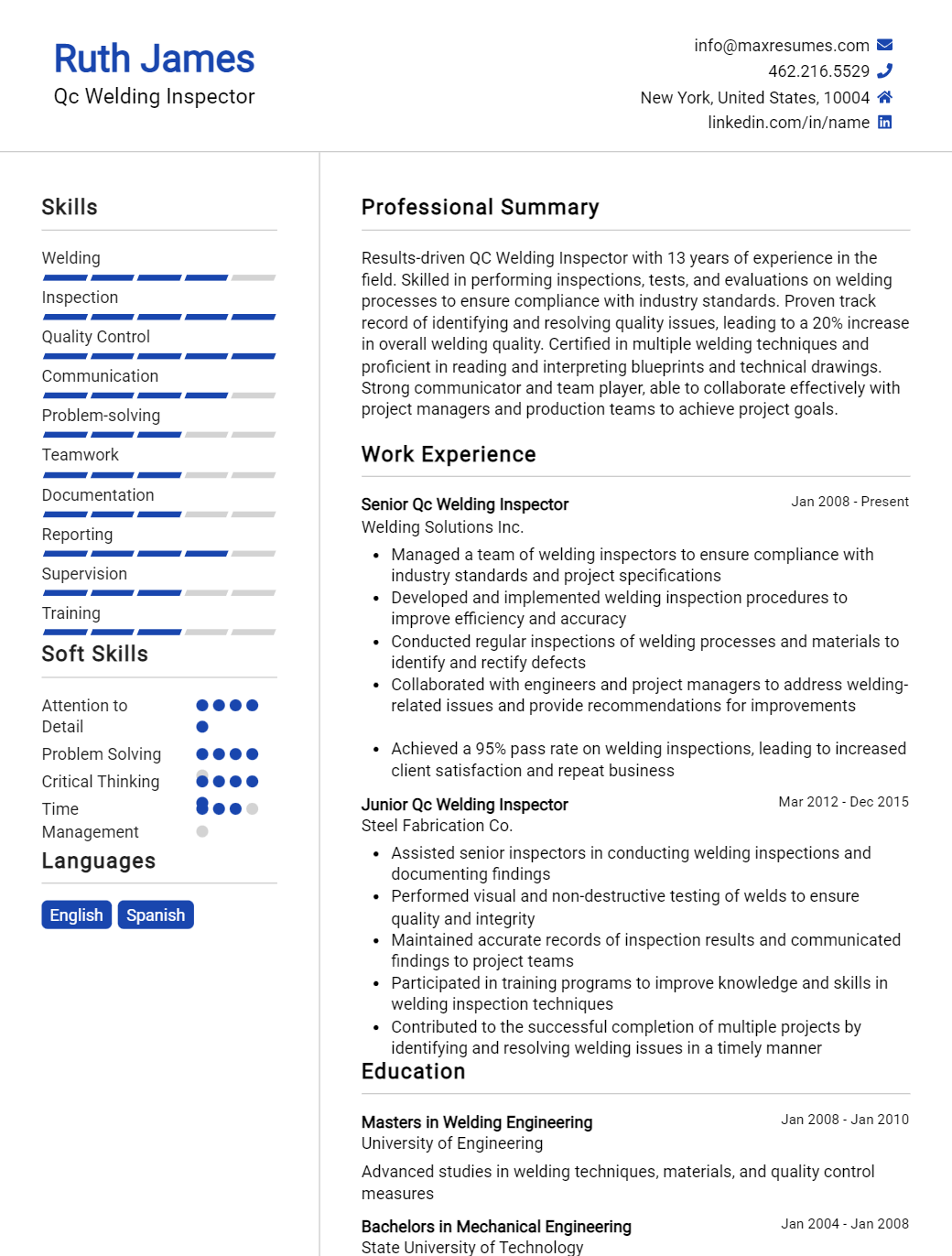

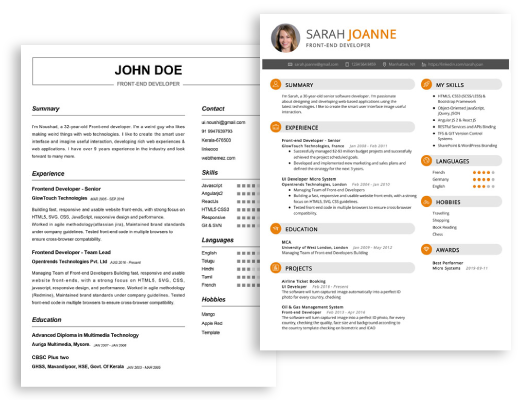

Welding Inspector Resume Sample

If you didn’t find what you were looking for, be sure to check out our complete library of resume examples.

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

Qc Welding Inspector Resume Examples

John Doe

Qc Welding Inspector

123 Main Street | Anytown, USA 99999 | Phone: (123) 456-7890 | Email: john.doe@email.com

I am a highly motivated and experienced Qc Welding Inspector with 5 years of experience in the oil and gas sector. I have an excellent eye for detail, ensuring that all inspection work is carried out to the highest of standards. I have a proven track record of ensuring that all welding is carried out correctly, in accordance with international standards and procedures. I am committed to upholding the highest standards of safety and quality assurance at all times.

Core Skills:

- Detailed knowledge of welding codes and standards

- Highly experienced in welding inspection for oil and gas operations

- Excellent attention to detail and quality assurance

- Strong problem- solving skills

- Proficient in MS Office Suite, AutoCAD and other engineering software

- Excellent communication and interpersonal skills

Professional Experience:

QC Welding Inspector, ABC Oil and Gas, 2015- 2020

- Performed welding inspections on parts and equipment in accordance with international standards and procedures

- Monitored the progress of welding operations to ensure completion in a timely and safe manner

- Conducted post- weld inspections to verify quality and accuracy of welds

- Identified and documented any welding protection and defects

- Created detailed reports on all inspections and welds

Education:

Bachelor of Science in Mechanical Engineering, ABC University, 2010- 2015

Qc Welding Inspector Resume with No Experience

Recent college graduate with a degree in welding engineering seeking to use my knowledge and skills to become a successful QA/QC Welding Inspector. Possess strong organizational skills and ability to understand complex welding concepts and design. Possess knowledge in ISO 9001 quality management systems and experience in applying concepts in quality auditing, inspection, and troubleshooting.

Skills:

- Proficient in welding engineering inspection processes

- Knowledge of welding engineering principles and techniques

- Excellent communication and interpersonal skills

- Highly organized and detail- oriented

- Ability to read and interpret blueprints

- Strong analytical and problem solving skills

Responsibilities:

- Inspect completed and partially completed welds for conformance to standards and quality requirements

- Conduct visual inspections to ensure welds meet required specifications

- Perform regular maintenance and calibration of inspection tools and equipment

- Document and report any discrepancies and non- conformance found

- Provide feedback to welders and production teams on welding and quality issues

- Maintain records of inspection results, measurements, and findings

- Communicate effectively with other departments, such as quality control and engineering, to ensure quality standards are met

Experience

0 Years

Level

Junior

Education

Bachelor’s

Qc Welding Inspector Resume with 2 Years of Experience

A highly motivated and dedicated Quality Control Welding Inspector with two years of experience in the welding industry. Possesses a solid working knowledge of welding inspection process, materials, and processes. Skilled in visual inspection, non- destructive testing, and weld evaluation. Ability to read and interpret blueprints and schematics. Able to perform a wide range of duties to ensure the quality of welds.

Core Skills:

- Welding Inspection Processes

- Nondestructive Testing

- Quality Assurance

- Visual Inspection

- Documentation

- Problem Solving

- Troubleshooting

- Blueprint Reading

Responsibilities:

- Conducted visual inspections, non- destructive tests, and weld evaluations of welded components.

- Ensured weld quality through the use of various inspection and testing equipment.

- Developed and maintained quality control documentation, including test results and records.

- Performed daily inspections of welded components and equipment to ensure compliance with specifications and codes.

- Troubleshot welding processes to identify and resolve issues.

- Analyzed and interpreted blueprints and schematics to determine appropriate tests and inspections.

- Assisted in the training of new inspectors and technicians.

Experience

2+ Years

Level

Junior

Education

Bachelor’s

Qc Welding Inspector Resume with 5 Years of Experience

A Qc Welding Inspector with 5 years of experience, I am highly knowledgeable and skilled in the areas of welding inspection, quality control, and non- destructive testing. I am an excellent communicator and team player who is able to carry out duties independently and accurately. I have the eye for detail and the ability to detect even the most minute defects. I am also experienced in the use of various welding inspection tools. I am confident that I have the skills and experience to make a positive contribution to any organization.

Core Skills:

- Welding Inspection

- Quality Control

- Non- destructive Testing

- Attention to Detail

- Problem- Solving

- Time Management

- Excellent Communication

- Team Player

- Ability to Work Independently

Responsibilities:

- Inspect welds for conformity to established standards

- Verify that all welding components are produced according to specifications

- Ensure quality control of all welds

- Inspect welding tools, equipment and materials for defects

- Record and report all inspections and tests

- Conduct non- destructive testing on welded parts

- Provide on- site training to welding personnel

- Monitor and review welding processes and procedures

- Assist with the development of welding test plans

- Maintain records of welding inspection and non- destructive testing results

Experience

5+ Years

Level

Senior

Education

Bachelor’s

Qc Welding Inspector Resume with 7 Years of Experience

A highly experienced and certified Qc Welding Inspector with 7 years of experience in the industry. Passionate about the craft, I have inspected a variety of welding components and equipment to ensure quality and timely completion of projects. I have excellent knowledge and experience in reading blueprints, inspecting welds and performing quality checks in accordance with ASME, AWS and API standards. My excellent communication skills and attention to detail ensure successful completion of each project.

Core Skills:

- Excellent knowledge of welding and cutting processes

- In- depth understanding of ASME, AWS and API standards

- Proficiency in reading blueprints and schematics

- Ability to identify and resolve welding defects

- Excellent communication skills

- Attention to detail and high level of accuracy

- A commitment to safety in the workplace

Responsibilities:

- Inspect welds, piping systems and equipment to ensure they meet quality standards

- Ensure all welding specifications are met

- Perform visual inspections to identify defects

- Inspect test pieces and samples to verify weld strength and integrity

- Manage and document any welding related repairs

- Read and interpret blueprints and schematics

- Maintain an accurate record of inspection results

- Ensure safety regulations are being followed

- Collaborate with production staff and management to ensure quality standards are being met

Experience

7+ Years

Level

Senior

Education

Bachelor’s

Qc Welding Inspector Resume with 10 Years of Experience

A highly experienced and versatile Qc Welding Inspector with more than 10 years of experience in the welding and fabrication industry.Known for having an exceptional eye for detail and an extensive knowledge of welding and inspection practices, I am adept at ensuring that product quality and safety are consistently met in a timely, accurate, and cost- effective manner. My expertise encompasses all welding, fabrication, and NDE processes, including MIG and TIG welding, material testing, inspection, and analysis. I am also an expert in the safe handling of hazardous materials and the implementation of efficient quality control procedures.

Core Skills:

- Inspection and Quality Control

- Welding and Fabrication

- NDE Processes

- Material Testing

- MIG/TIG Welding

- Hazardous Material Handling

- Safety Compliance

- Report Writing

- Regulatory Compliance

Responsibilities:

- Conduct inspections and tests to ensure that products meet quality and safety standards

- Perform Visual and Dimensional Inspections on welded components

- Ensure accuracy of welds and their code compliance

- Review drawings and welding procedures to ensure quality and safety

- Inspect and approve incoming materials for welding and fabrication

- Develop and maintain welding and fabrication quality control standards

- Prepare reports on inspection findings, welding results, and other related data

- Conduct mechanical testing and analysis on welds, metals, and other materials

- Ensure compliance with applicable codes and standards

- Maintain a safe work environment by adhering to all safety regulations and procedures.

Experience

10+ Years

Level

Senior Manager

Education

Master’s

Qc Welding Inspector Resume with 15 Years of Experience

A highly experienced Qc Welding Inspector with 15 years of experience in quality control and welding inspection. Experienced in supervising welding operations and ensuring that all welding activities meet the relevant safety and quality standards. Possess superior knowledge of welding processes, welding inspection techniques and welding safety procedures. Able to work well within a team and independently to ensure that all welding activities meet the highest standards.

Core Skills:

- Supervising welding operations

- Welding processes

- Welding inspection techniques

- Quality control

- Safety and quality standards

- Welding safety procedures

- Data analysis

- Problem solving

- Written and verbal communication

- Time management

Responsibilities:

- Inspecting welding teams during operations to ensure that all safety and quality standards are met.

- Monitoring welding operations and equipment to ensure that all processes are being followed correctly.

- Identifying any defects or problems with welds and reporting them to the relevant personnel.

- Evaluating welds to ensure that they meet the relevant specifications.

- Performing data analyses to monitor the quality of welds and the performance of welding teams.

- Ensuring that all welding activities are completed in a safe and efficient manner.

- Providing guidance and support to welding teams to ensure that all welding activities are performed correctly.

- Maintaining up- to- date records of all welding activities.

- Providing reports on welding operations and results to management.

- Ensuring that all welding personnel are aware of and comply with safety regulations.

Experience

15+ Years

Level

Director

Education

Master’s

In addition to this, be sure to check out our resume templates, resume formats, cover letter examples, job description, and career advice pages for more helpful tips and advice.

What should be included in a Qc Welding Inspector resume?

Having the right resume for a Quality Control (QC) Welding Inspector position can be the difference between getting your dream job and being passed up for the position. To give yourself the best chance of getting an interview, it’s important that your resume includes the right information. Here are some key elements to include in your QC Welding Inspector resume:

- Education: List any degrees or certifications that are relevant to your welding knowledge and experience.

- Experience: Include any QC welding inspector positions you have held, as well as any other welding experience.

- Skills: List any applicable welding skills, such as knowledge of welding procedures, codes and standards, ability to interpret blueprints, and safety awareness.

- Specialized Knowledge: Outline any specialized knowledge you have in welding inspection and testing.

- Knowledge of Equipment: Be sure to note any experience working with welding equipment and tools.

- Certifications: List any certifications that are relevant to the position you are applying for.

- Innovative Problem Solving: Showcase any problem-solving skills that you used in previous welding inspections.

- Professionalism: Demonstrate your professional skills and ability to effectively communicate with a wide range of personnel.

- Flexibility: Show that you have the ability to work in a variety of welding settings.

By highlighting your experience and skills in a QC Welding Inspector resume, you’ll give yourself the best chance of getting your dream job.

What is a good summary for a Qc Welding Inspector resume?

A Qc Welding Inspector resume should include a comprehensive overview of the candidate’s qualifications, experience, and skills. The summary should highlight the candidate’s ability to inspect and evaluate welding processes, and should demonstrate their knowledge of relevant codes and regulations. The summary should also mention the candidate’s experience in developing and implementing quality control procedures, as well as their ability to work as part of a team. Additionally, the summary should showcase the candidate’s attention to detail, problem-solving abilities, and communication skills. By providing a well-written summary, a Qc Welding Inspector resume can help the candidate stand out from the competition and get noticed by employers.

What is a good objective for a Qc Welding Inspector resume?

A Quality Control (QC) Welding Inspector is responsible for ensuring all weld joints meet quality and safety standards. For those looking to apply for a QC Welding Inspector position, here are some tips for a good objective statement for your resume:

- Demonstrate the ability to inspect welds for quality and compliance with industry standards.

- Demonstrate knowledge of American Welding Society (AWS) and American Society for Nondestructive Testing (ASNT) standards.

- Proven experience in reading and interpreting blueprints, technical data, and weld symbols.

- Proficient in using a variety of instruments, metallurgic evaluation, and other non-destructive testing methods.

- Familiarity with safety and health regulations pertaining to welding.

- Demonstrated ability to work independently and as part of a team.

- Experience in providing written and verbal communication of inspection findings.

How do you list Qc Welding Inspector skills on a resume?

When it comes to listing welding inspector skills on a resume, it is important to include both your technical knowledge and qualifications as well as any other skills that may be relevant. Here are some tips to consider:

- Include any relevant certifications, such as the American Welding Society (AWS) Certified Welding Inspector (CWI), the American Society of Mechanical Engineers (ASME) Certified Inspector, or any other welding inspector certifications.

- Describe the materials and processes you are familiar with, including metals and alloys, welding techniques, and inspection techniques.

- Detail your knowledge of relevant codes and standards, such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code.

- Showcase your ability to use inspection and measuring tools, such as calipers, micrometers, gauges, and other devices.

- Demonstrate your ability to interpret blueprints and technical documents.

- Describe your knowledge of industry terminology.

- Highlight your problem-solving and critical thinking skills.

- Draw attention to your strong communication and organization skills.

- List any additional technical and professional training you have received.

What skills should I put on my resume for Qc Welding Inspector?

QC Welding Inspectors are highly sought-after positions that require both technical and practical skills to be successful. When creating a resume for a QC Welding Inspector position, it’s important to highlight your relevant qualifications and experience. Here are some of the key skills you should put on your resume:

- Knowledge of welding processes and safety standards: QC Welding Inspectors should be knowledgeable about welding processes and safety standards, including ASME and AWS codes.

- Ability to read and interpret blueprints: QC Welding Inspectors must be able to read and interpret blueprints and Quality Control documents.

- GMP (Good Manufacturing Practices) experience: QC Welding Inspectors should have experience with GMP, including the ability to perform detailed inspections and record-keeping.

- Computer literacy: QC Welding Inspectors should be proficient in computer applications, including Microsoft Office and any relevant software programs.

- Ability to analyze data: QC Welding Inspectors should be able to analyze data and report results.

- Excellent communication skills: To be successful, QC Welding Inspectors need to be able to communicate effectively with coworkers and supervisors.

By highlighting your knowledge and experience in the areas above, you’ll be able to demonstrate your qualifications and stand out in the hiring process.

Key takeaways for an Qc Welding Inspector resume

When applying for a welding inspector job, crafting your resume can make all the difference in securing the job you want. As a welding inspector, you need to demonstrate a solid background in conducting quality control inspections of weldment work pieces. Here are some key takeaways to include on your resume that will help you stand out:

- Highlight your certifications: When it comes to welding inspection, relevant certifications, such as American Welding Society (AWS) Certified Welding Inspector, will set you apart from other applicants. Be sure to list your certifications prominently on your resume.

- Show off your experience: Be sure to include a comprehensive list of your previous welding inspection experience. Any experience you have in conducting NDT inspections, designing and implementing weld documents, or working with equipment and machinery should be included.

- Detail your knowledge of codes and standards: As a welding inspector, you should be able to demonstrate a strong knowledge of welding codes and standards. Be sure to include a list of the codes and standards you are familiar with, as well as any programs or software products you are proficient in.

- Demonstrate your attention to detail: The success of a welding inspector relies on their attention to detail. Be sure to highlight the detail-oriented nature of your work, and any instances where you have successfully caught errors or defects.

By emphasizing your certifications, experience, knowledge of codes and standards, and attention to detail, you can ensure that your resume will stand out from the competition. Following these key takeaways will help you put your best foot forward when applying for a welding inspector job.

Let us help you build

your Resume!

Make your resume more organized and attractive with our Resume Builder